The technological world is currently facing a huge problem in the form of a shortage of chips. Moreover, this problem is so extensive that it also affects the automobile industry, due to which car companies are not able to produce enough cars. For example, even the domestic Škoda has several thousand cars in parking lots that are still waiting for their completion - they lack the basic chips. However, after the introduction of the latest iPhone 13, an interesting question arises. How is it possible that new apple phones are normally sold as far as possible, while you have to wait a year for a new car?

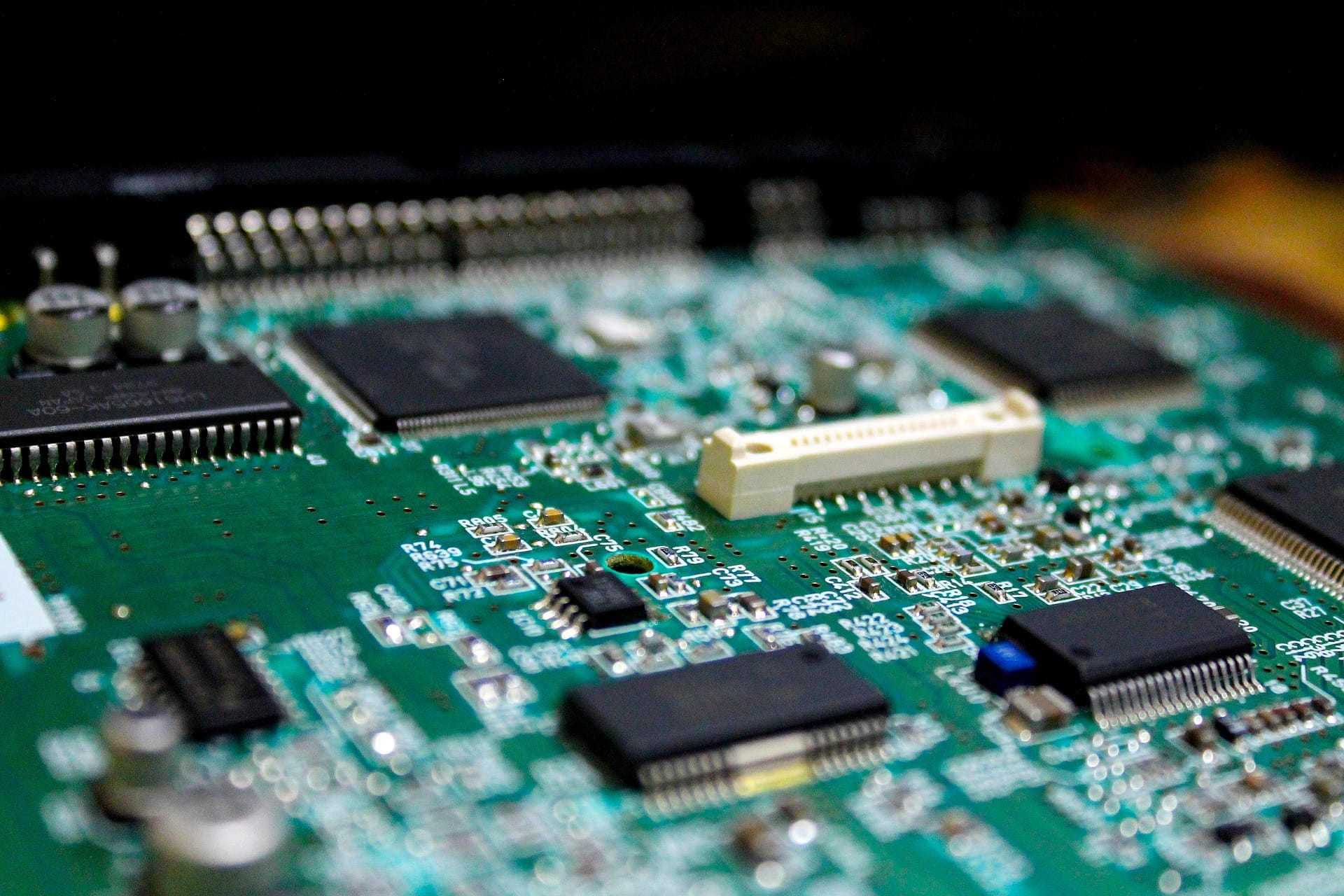

The new iPhone 13 (Pro) is powered by the powerful Apple A15 Bionic chip:

The pandemic and the emphasis on electronics

If you're one of our regular readers, you certainly haven't missed it article justifying the current chip crisis. The biggest problems started together with the arrival of the covid-19 pandemic, in any case, there were certain complications in the chip (or semiconductor) manufacturing sector long before that. Even before the outbreak of the pandemic, the media pointed out their possible shortage.

It could be interest you

But what effect does covid-19 have on the lack of chips? With the vision of reducing the risk of infection, companies have moved to the so-called home office and students to distance learning. A large part of the workers and students therefore operated directly from their homes, for which they understandably needed high-quality equipment. It is therefore not surprising that the demand for computers, tablets, webcams and other consumer electronics increased during that period.

Problems in the automotive industry

At the beginning of the pandemic, everyone had to be more careful when it came to finances. Some companies were laying off their employees and it was not so clear whether the individual in question would eventually end up without a job. This is precisely why a drop in demand on the car market was expected, to which chip manufacturers responded and began to orient their production towards consumer electronics, which were in much greater demand. Exactly this could answer the question of why the latest apple phone is now available, even in four versions, while you still have to wait for some car models.

To make matters worse, there is one more, much bigger problem. While the pandemic appeared to be the trigger for this whole situation, it is far from over in the case of the expected lower demand. Car manufacturers are running out of common chips without which they cannot complete their cars. These are semiconductors at a fraction of the price of the entire car. However, logically, without them, the given model cannot be sold as complete. Most often, these are really primitive chips managing the operation of brakes, airbags or simply opening/closing windows.

Intel saves the automotive market! Or not too?

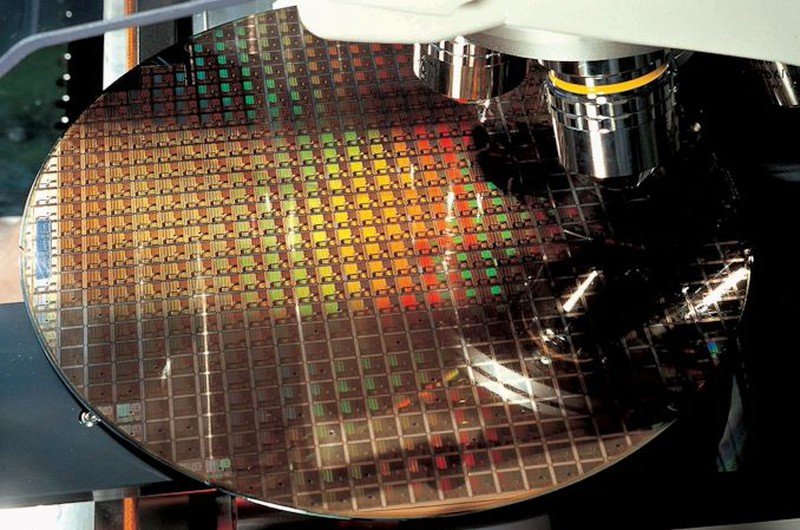

Pat Gelsinger, who is the CEO of Intel, stepped forward as a self-proclaimed savior. During his visit to Germany, he said that he would supply the Volkswagen Group with as many chips as they wanted. The problem, however, is that he meant chips based on the 16nm manufacturing process. Although this value may seem ancient to Apple fans, since the aforementioned iPhone 13 is powered by an A15 Bionic chip with a 5nm manufacturing process, the opposite is true. Even today, car companies rely on even older chips with a production process between 45 nm and 90 nm, which is a real stumbling block.

This fact also has a simple justification. Electronic systems in cars are often critical and must therefore function in a wide variety of conditions. This is precisely why manufacturers still rely on older, but years-proven technology, for which it is not a problem to operate safely regardless of the current temperature, humidity, vibrations or unevenness on the road. However, chip manufacturers are unable to mass-produce similar chips, as they have long since moved on to a completely different place and do not even have the production capacity for something similar. It would therefore be best for the automotive industry if these technological giants invested in the mentioned capacities and started producing significantly older chips as well.

Why not build factories on older chips?

Unfortunately, this does not make sense for the semiconductor manufacturers themselves, for whom this would be a fat investment, from which they would retreat again after a while, as the automotive industry is also moving forward, albeit slowly. In addition, a member of the board of directors of the Volkswagen Group mentioned that because of the 50-cent chips (CZK 11), they cannot sell cars worth 50 thousand dollars (CZK 1,1 million). Leading companies protecting semiconductor production, such as TSMC, Intel, and Qualcomm, have invested billions of dollars in recent years to improve their technologies and have moved forward at a rocket pace. This is exactly why we have powerful smartphones and computers today. However, this shift negatively affects the automotive industry, which instead of the "worthless" chips it needs for its products, only has access to more modern ones.

It could be interest you

So with a bit of exaggeration, you could say that automakers need a chip for the iPhone 2G, but they can only get what powers the iPhone 13 Pro. Both segments will either have to find a common language, or car companies will start protecting chip production themselves. How the situation will continue to develop is understandably unclear. The only thing that is certain is that it will take several years to return to normal.

Adam Kos

Adam Kos

Unfortunately, I have completely different information directly from Skoda and VW chips, neither new nor old.... The question is why? It's much better to let the customer wait and negotiate the price.

You have direct access to conspiracy theories, congratulations. Business doesn't work in a way that you stock a few pieces, raise the price and break production.

The automakers themselves are somewhat to blame for this. I understand that there was less demand for cars for a while, but I don't understand that they don't have someone there who can look into the future a little and tell them that if you cancel those orders, someone else will jump on them and then they will just have to to wait or even in the worst case, they don't even get to them anymore, because the possibilities are simply not endless.

Does anyone from the local Apple Store remember the early days of the iPhone? I do. And there was no iPhone 2G, just an iPhone. Apple never named it the iPhone 2G. The iPhone 3G had a similar designation.

He is right, Chairman. There was no iPhone 2G.

If I take it, I have a chip in the iPhone produced by a 5nm supermodern process, but if it weren't for TSMC, Apple itself wouldn't even make a fart. Intel uses the 16nm process but has the advantage that it designs and manufactures the chip itself.

Can any of you critics help car companies around the world redesign their software, their motherboards and all the connected components they use in cars for new processors. For new, untested processors. And then you buy a car that doesn't have a bitten chip. And then consider one more fact. Why are all ATMs equipped with old processors and using windows ce as software? Why probably? Why is it more effective to hit someone over the head with a brick than to eliminate them with a nuke?

You will probably also have a tested processor 😂😂😂

Incredible trepanice and tliachanice worthy of 10 beers. At all, I have absolutely no information about what chips cars or ATMs use. But even with those ATMs, I would rather doubt that it has anything to do with nm technology. But rather due to the design and technology of the chips, unfortunately Windows XP, which I assume you use, or Android simply cannot work on all types of processors. If you know why, fine, if not, your problem... So if I can make new modern control systems that work continuously, whether in production lines or industrial technology, work de facto non-stop. 16nm technology is not at all an obstacle for use in cars, and excuses like "they are not tested" are true, but the car manufacturers are to blame, don't tell me that battery thermal management, or power management for the engine, or navigation, or traffic sign recognition brands is processed by a processor the size of a suitcase?! And when the car is parked in winter or warm weather, the processor still works in the temperature range of -20 +50 at least