In the pilot of our new series, Getting Started with Engraving, we looked at a general introduction to engraving, as well as safety and other information related to shopping at Chinese marketplaces. I honestly had no idea that this series could be so successful and that readers could like it. That's why I decided to bring home engraving a little closer to you, so that you too can engrave at home without any problems. In this piece, we'll look at how to choose the right engraver to suit your needs.

It could be interest you

First, you need to find a Chinese marketplace to order from. Honestly, I don't dare to order expensive electronics from AliExpress, but from marketplaces that are designed for buying electronics. Concerns are probably quite unnecessary in this case, but it should be noted that you will not find such a selection of engraving machines on AliExpress as on other marketplaces focusing on electronics. At the same time, you often have free express shipping on such marketplaces, whereas on AliExpress you would have to pay for it or wait several weeks for delivery. I definitely recommend that you order the engraver from well-known and proven markets, where there will be no problem with a claim if the shipment is damaged or lost. Once you find the right marketplace, you can start exploring it.

If you want to search for engraving machines, just type in the search engine engraver whether engraving tool. Immediately afterwards, you will see a menu of all available engravers. Personally, I immediately sort all the searched products according to the number of orders, from the largest number to the smallest. It doesn't mean that what is bought the most is necessarily the best, but in my case it has always worked for me when buying more expensive products. After sorting, you just need to clarify a few aspects, i.e. what exactly you require from the engraving machine. The machines shown are certainly not the same, although they may use similar or identical parts. In this case, it is therefore necessary to choose the machine that will best suit your requirements.

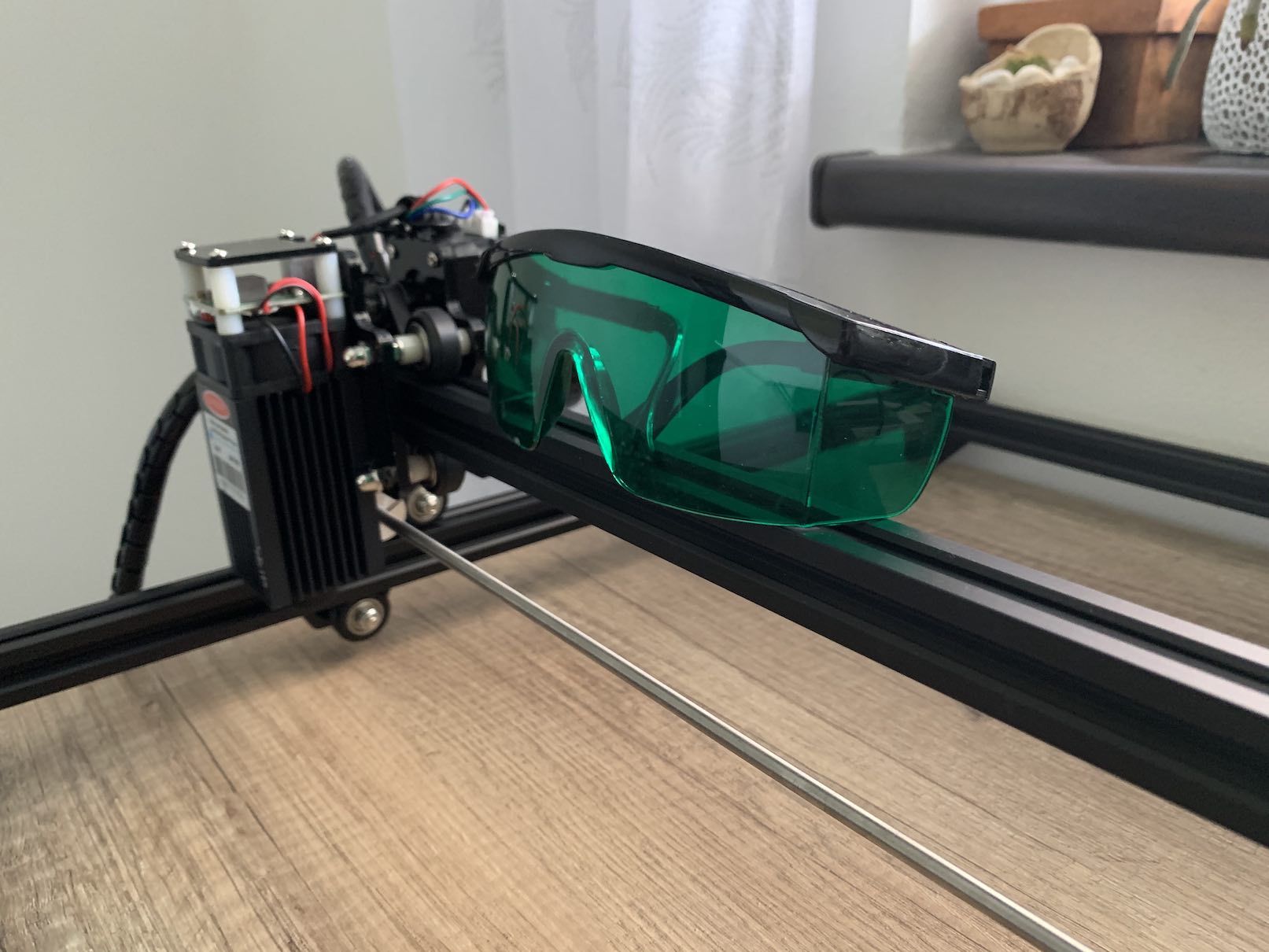

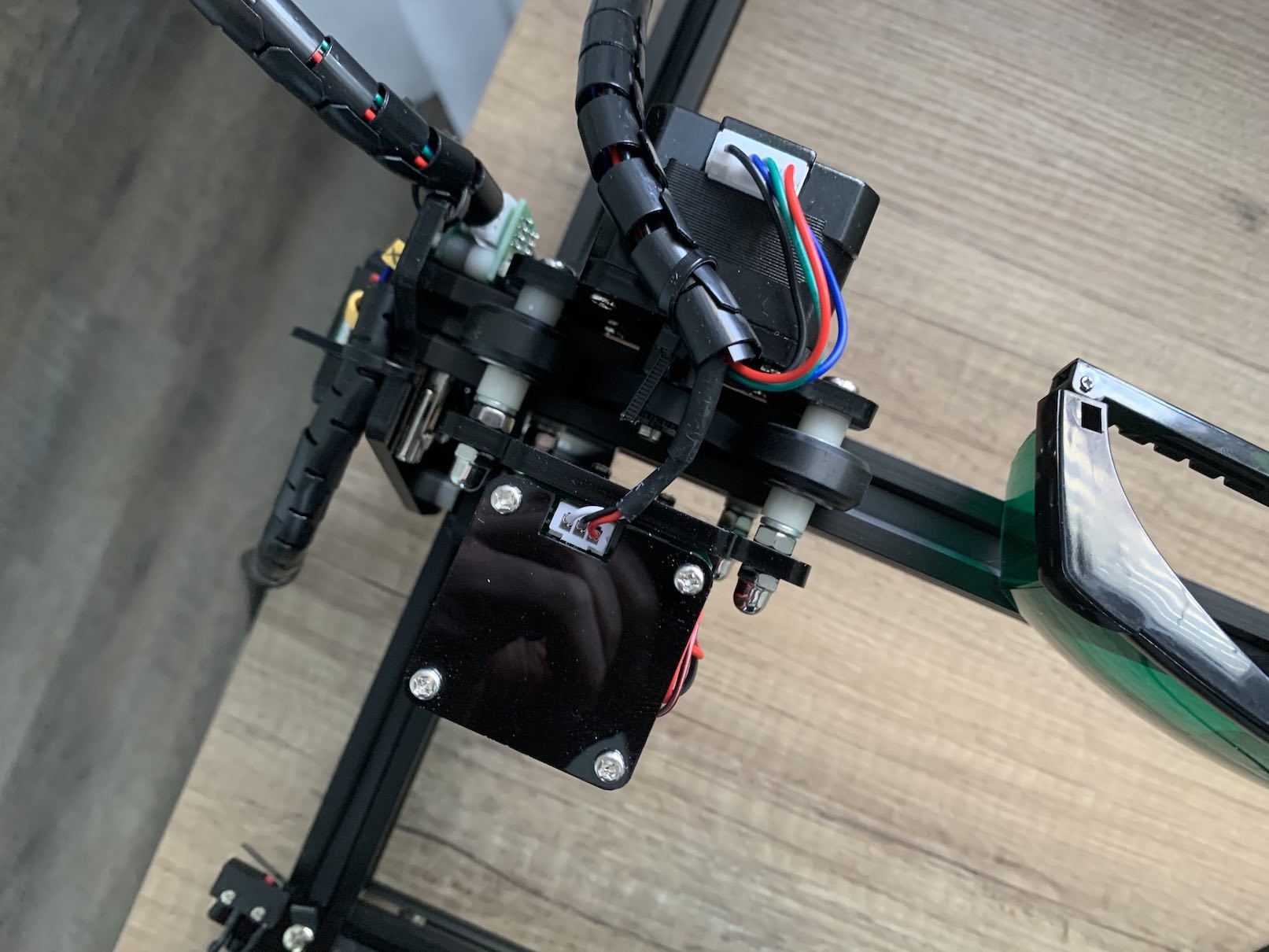

First, of course, you should clarify how much money you want to sacrifice for the purchase of an engraving machine. As soon as you clarify the maximum price tag, your choice becomes much smaller. At the same time, you cannot expect that an engraver for two thousand crowns will be able to do the same or more than an engraver for ten thousand. In practically all cases with engravers, the more expensive they are, the more they offer. You also need to think about what materials you want to burn or cut with the engraver. If you only want to burn into wood or some fabric, a weaker and cheaper engraver will suffice. However, if you want to cut wood and at the same time, for example, burn into iron, then it is necessary to take a more expensive and stronger engraving machine. When describing an engraver it is always necessary that you look at the performance of the laser and not the performance of the engraver itself. It is difficult to determine how powerful a laser can engrave in iron, in any case, in all cases you will find true information about what materials the engraver can be used on in the detailed description. I personally own the 15W version of the ORTUR Laser Master 2 with a laser power of 4000 – 4500 mW. With such strength I am able to cut wood and engrave iron. Update: ORTUR now has its own e-shop, where you can buy an engraver quickly, easily and safely.

You can buy ORTUR engravings here

Another, very important aspect is the overall size of the engraving machine, i.e. on how large an area the machine will be able to operate. In the last part of this series, I mentioned my first engraver, which I bought for about two thousand crowns. She was only able to engrave on an area of 4 x 4 centimeters, which is certainly not much these days. My new engraver ORTUR Laser Master 2 can already work on an area of approx. 45 x 45 centimeters, which is enough for most work. At the same time, keep in mind that if you take a huge engraver and want to engrave tiny objects, it will be very difficult to get the engraved pattern straight. At the same time, you must take into account the accuracy of the engraver. Even though the engraving machines themselves are very accurate, when engraving tiny objects, the pattern can "split" and in the end it will not look good at all.

It could be interest you

The material from which the engraver is made is also important. After previous experience, I would definitely avoid engravers with a plastic design, for several reasons. It can easily happen that the plastic bends or breaks in some way (during transport, folding or during operation). In addition, it occurs to me that the engraver is simply a machine that definitely deserves an iron chassis. So if you have the budget for it, definitely go for an engraver that has an iron body. In addition, you should also be interested in what programs the engraving machine supports. When choosing, I recommend that the engraver supports LaserGRBL and possibly also Lightburn. The first named program is free and will suffice for most users, Lightburn is then paid and offers extended functions. Both of these programs work really well for me and I can recommend them from my own experience. Other functions and features are more just safety and additional - for example, a sensor for unusual movements, after detection of which the entire engraver will be turned off to prevent fire, etc. These are not functions that are needed, but they are definitely a good bonus.

This is also how the final products made with the engraving machine can look like:

The purchase process is then exactly the same as I mentioned in the last part. Please note that for all engraving machines over 22 euros you will pay VAT, over 150 euros then VAT together with customs duty. In certain cases, the purchase can be quite expensive. In the next part, we will look together at the process of assembling the engraver, together with a certain form of calibration. The correct assembly of the engraver is absolutely crucial to ensure that the machine is accurate and that there are no various artifacts that especially beginners have big problems with. I will certainly not keep all my tips and observations to myself and I will be happy to share with you advice on how to build the engraver as best as possible.

You can buy ORTUR engravings here

Great, thanks for the next part... :)

I was really looking forward to this topic, but the article is somehow about nothing, I would have expected some facts and practical experience, not info of the type - choose a store that suits you, choose the parameters as you see fit... and info that I will cut wood :) – what kind of wood, for how long ... it will go so and so with this and that execution ... I didn't learn anything here that would help me with anything :(

Exactly. There is nothing in the article that does not come to mind by itself. No useful information from practice :-(

And have you read the other 5 parts?

Nice series! Just a note, in the industry it's called an engraver.

Thanks for the info, I will use it!

Why isn't the store where you bought it listed??? Or at least count, that's how useless the information is.

Hello, please email me pavel.jelic@letemsvetemapplem.eu. I will be happy to send you links to the engraver along with stores where it can be purchased. Thank you and have a nice day.

Hello. I also want to equip myself with a laser. I mainly need something to cut templates from thin plywood for copying with a router, but I also like to burn signs or other images. Mainly in wood. If I understand it correctly, 5500mW should be more than enough for me. Thanks for the great work.

I have a 15w engraver, i.e. 15.000mw and I don't even burn a fart into iron, wood is fine... pictures, logos, whatever, but it can't do any metal. And it wasn't cheap, it cost about 12.000 CZK, of course they say in the description that it can do stainless steel, but not aluminum anymore and not iron either.. in my opinion, stainless steel is much harder than aluminum and iron, so I have no idea where the problem is.. any advice on e-mail..thank you..j.csoka@seznam.cz

Hello, can you please advise me how to find a verified marketplace? I am interested in Ortur Lazer Master 2 and 15w, but it is only offered on foreign portals and I do not want to order it. I would rather follow the tried and tested path you recommend, but I don't know where to start, where to get it here in the Czech Republic? Thank you, University

Hello, it is not worth buying in the Czech Republic. For one thing, there aren't many of them here, and if they are, then with a big markup. Take a look at the official website ortur.net, where you can also find the new Ortur Laser Master 2 Pro, which is better in every way.

Hi, I have a question, I have a MacBook Air, so if I buy the Ortur Laser Master 2 PRO, will I not be able to use the Laser GRBL program and therefore not import photos, etc. much? Or will LightBurn replace the same functions for me? Alternatively, do you have experience with the Engraver Master program?

and one more question please, how can this engraver work with such small objects? Respectively, you write in the text that a large engraver will have a problem working with small objects...does this also apply to this engraver? Thank you

Hello, which engraving would you recommend for stainless steel please? Can multiple pieces be engraved (I mean, for example, a magazine-feeder for multiple pieces)? Or does it have to be done one at a time? Thank you very much for your answer.