Anyone who has purchased an iPhone or other Apple product has seen a notice on the packaging stating that the product is designed in California. But that does not mean that its individual components are also produced there. The answer to the question of where the iPhone is made, for example, is not simple. Individual components do not come only from China, as many may think.

Production and assembly - these are two completely different worlds. While Apple designs and sells its devices, it does not manufacture their components. Instead, it uses suppliers of individual parts from manufacturers around the world. They then specialize in specific items. Assembly or final assembly, on the other hand, is the process by which all individual components are combined into a finished and functional product.

It could be interest you

Component manufacturers

If we focus on the iPhone, then in each of its models there are hundreds of individual components from different manufacturers, who usually have their factories all over the world. It is therefore not uncommon for a single component to be produced in multiple factories in multiple countries, and even on multiple world continents.

- Accelerometer: Bosch Sensortech, headquartered in Germany with offices in the US, China, South Korea, Japan and Taiwan

- Audio chips: US-based Cirrus Logic with offices in the UK, China, South Korea, Taiwan, Japan and Singapore

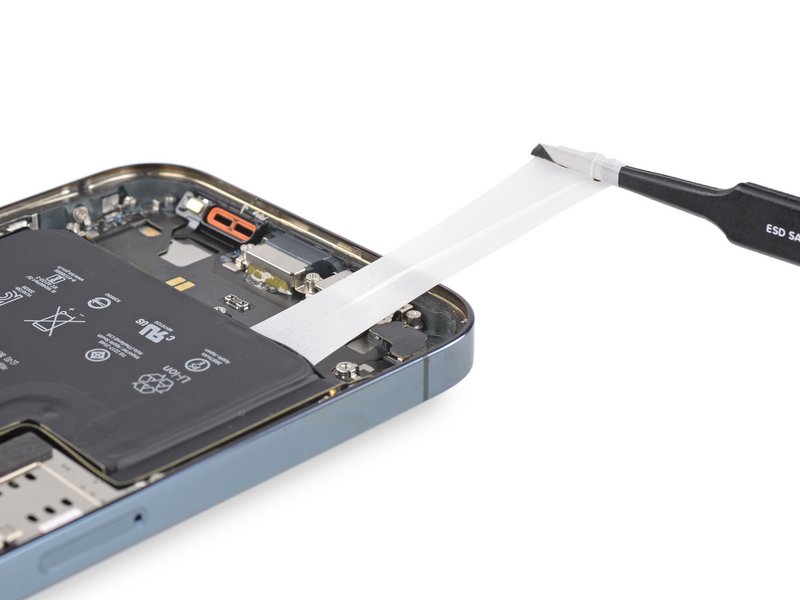

- Battery: Samsung headquartered in South Korea with offices in 80 other countries worldwide; Sunwoda Electronic based in China

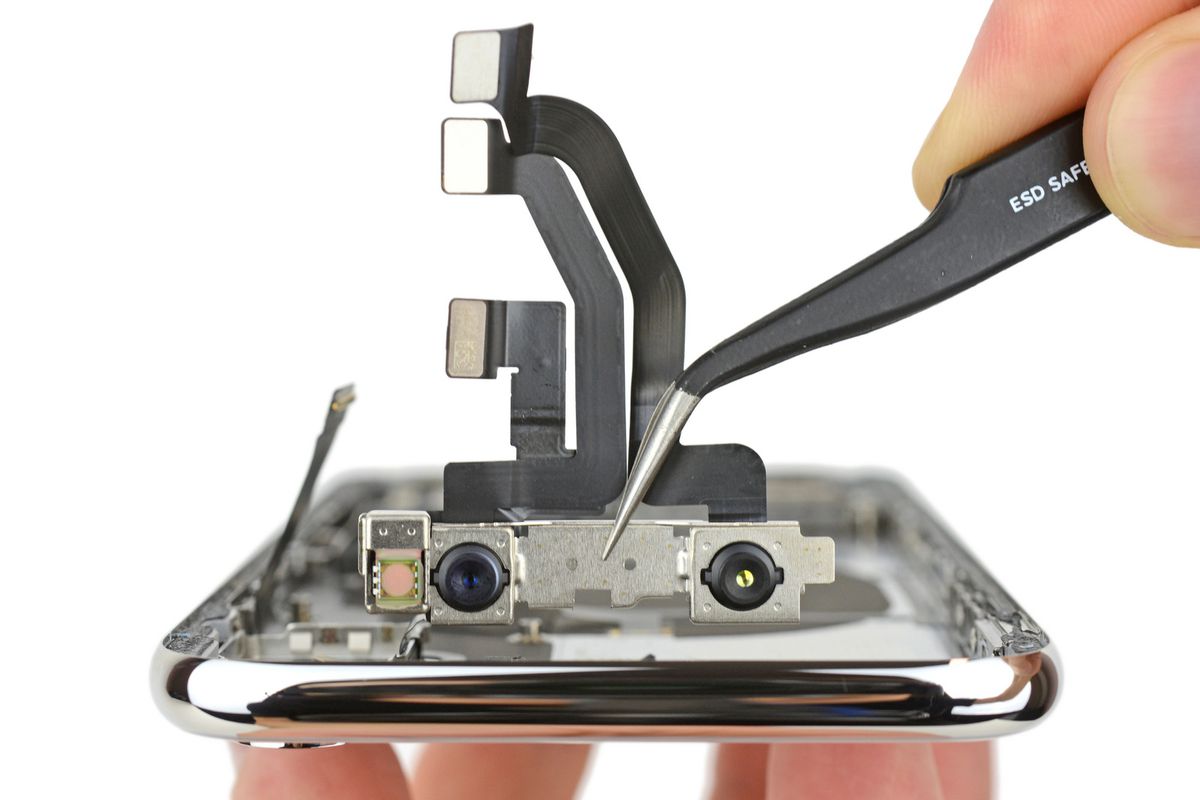

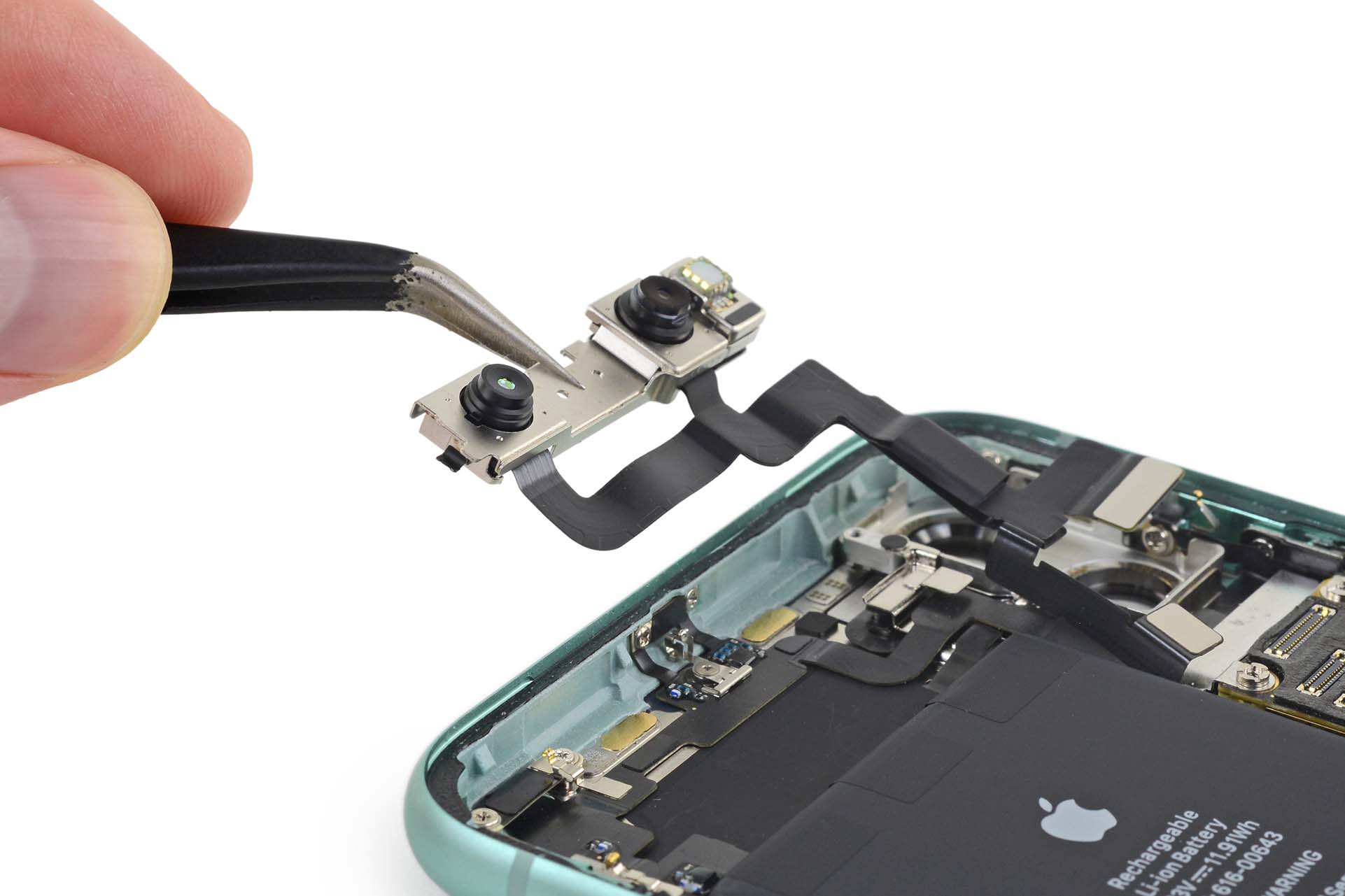

- Camera: US-based Qualcomm with offices in Australia, Brazil, China, India, Indonesia, Japan, South Korea and many other locations in Europe and Latin America; Sony is headquartered in Japan with offices in dozens of countries

- Chips for 3G/4G/LTE networks: Qualcomm

- Kompas: AKM Semiconductor headquartered in Japan with branches in the US, France, England, China, South Korea and Taiwan

- Display glass: Corning headquartered in the US, with offices in Australia, Belgium, Brazil, China, Denmark, France, Germany, Hong Kong, India, Israel, Italy, Japan, South Korea, Malaysia, Mexico, Philippines, Poland, Russia, Singapore, Spain , Taiwan, the Netherlands, Turkey and other countries

- Display: Sharp, with headquarters in Japan and factories in 13 other countries; LG is headquartered in South Korea with offices in Poland and China

- Touchpad controller: US-based Broadcom with offices in Israel, Greece, UK, Netherlands, Belgium, France, India, China, Taiwan, Singapore and South Korea

- gyroscope: STMicroelectronics is headquartered in Switzerland and has branches in 35 other countries around the world

- Flash memory: Toshiba headquartered in Japan with offices in over 50 countries; Samsung

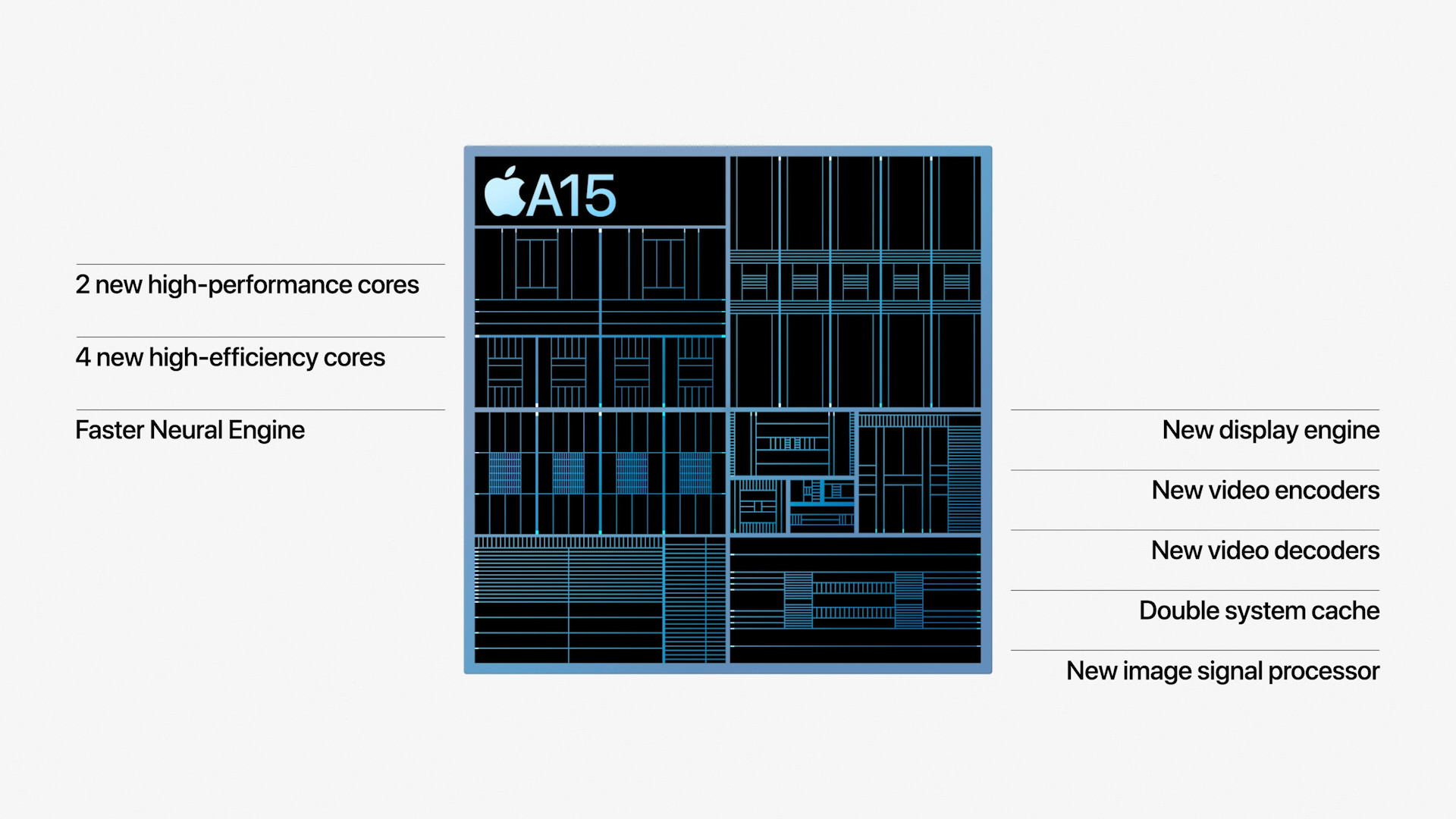

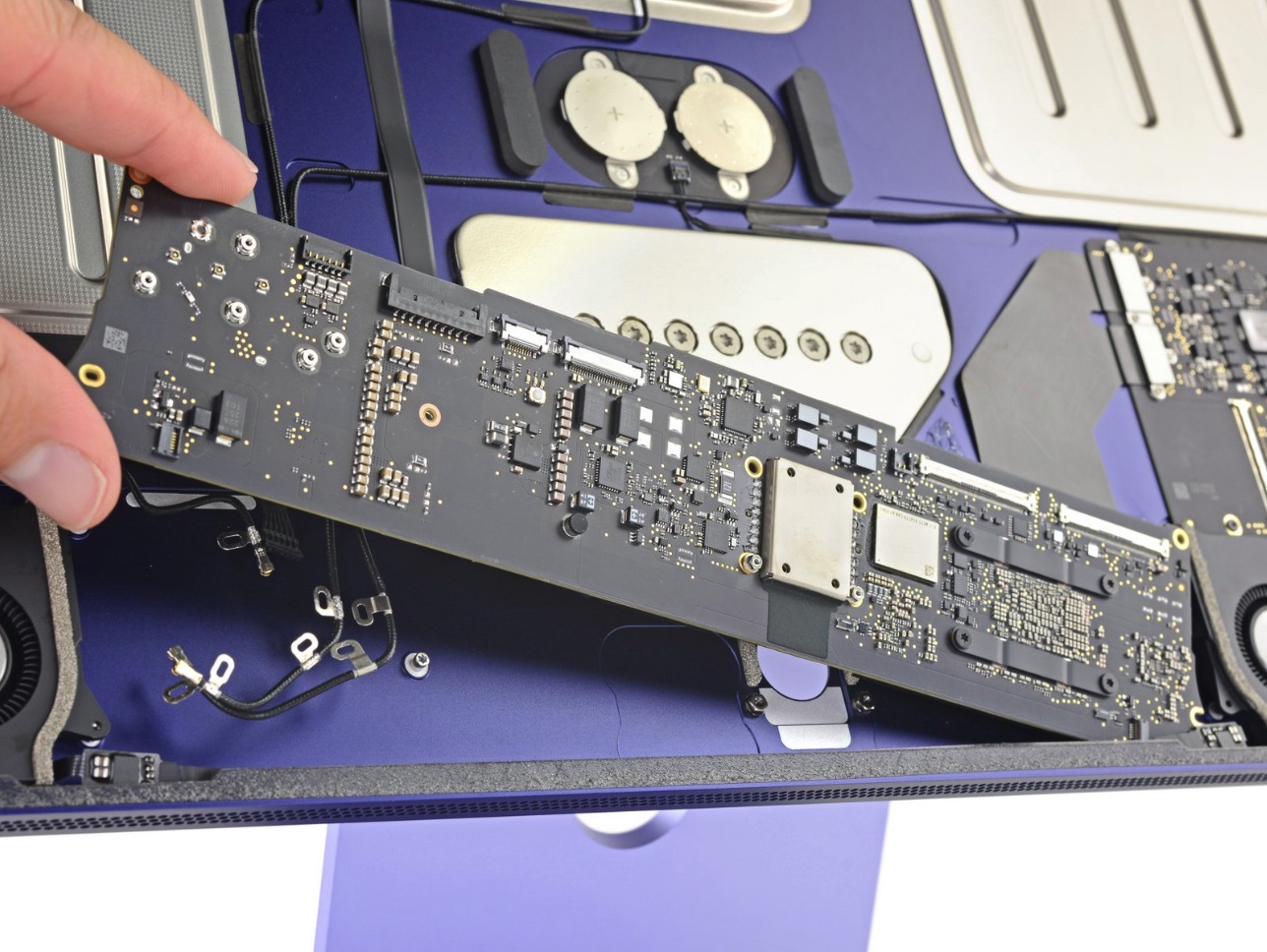

- A series processor: Samsung; TSMC is headquartered in Taiwan with offices in China, Singapore and the US

- Touch ID: TSMC; Xintec in Taiwan

- Wi-Fi chip: Murata based in the USA with offices in Japan, Mexico, Brazil, Canada, China, Taiwan, South Korea, Thailand, Malaysia, Philippines, India, Vietnam, Netherlands, Spain, UK, Germany, Hungary, France, Italy and Finland

Assembling the final product

The components produced by these companies around the world are ultimately sent to only two, which assemble them into the final form of an iPhone or iPad. These companies are Foxconn and Pegatron, both based in Taiwan.

Foxconn has been Apple's longest-standing partner in assembling current devices. It currently assembles most iPhones in its Shenzhen, China location, although it operates factories in countries around the world, including Thailand, Malaysia, Czech Republic, South Korea, Singapore and the Philippines. Pegatron then jumped into the assembly process with the iPhone 6, when about 30% of the finished products came out of its factories.

It could be interest you

Why doesn't Apple make the components themselves

At the end of July this year to this question he answered in his own way CEO Tim Cook himself. Indeed, he stated that Apple will choose to design its own components rather than source third-party components if it concludes that it "can do something better." He said so in connection with the M1 chip. He considers it to be better than what he can buy from suppliers. However, this does not mean that he would produce it himself.

It is then a question whether it would even make sense for him to build such areas with factories and drive an incredible number of workers into them, who would cut one component after another, and right after them, others would assemble them into the final form of the product, in order to churn out millions of iPhones for the greedy market. At the same time, it is not only about human power, but also machines, and above all the necessary know-how, which Apple does not actually have to worry about in this way.

Adam Kos

Adam Kos