The core of Apple phones is their chipset. In this regard, Apple relies on its own chips from the A-Series family, which it designs itself and then hands over their production to TSMC (one of the world's largest semiconductor manufacturers with the most modern technologies). Thanks to this, it is able to ensure excellent integration across hardware and software and to hide significantly higher performance in its phones than competitor phones. The world of chips has gone through a slow and incredible evolution over the past decade, improving literally in every way.

It could be interest you

In connection with chipsets, the manufacturing process given in nanometers is often mentioned. In this respect, the smaller the manufacturing process, the better it is for the chip itself. The number in nanometers specifically indicates the distance between two electrodes - source and gate - between which there is also a gate that controls the flow of electrons. Simply put, it can be said that the smaller the production process, the more electrodes (transistors) can be used for the chipset, which then increases their performance and reduces energy consumption. And it is precisely in this segment that miracles have been happening in recent years, thanks to which we can enjoy increasingly powerful miniaturization. It can also be seen perfectly on the iPhones themselves. Over the years of their existence, they have encountered several times the gradual reduction of the production process for their chips, which, on the contrary, has improved in the field of performance.

Smaller manufacturing process = better chipset

For example, such an iPhone 4 was equipped with a chip Apple A4 (2010). It was a 32-bit chipset with a 45nm manufacturing process, the production of which was ensured by South Korean Samsung. The following model A5 continued to rely on the 45nm process for the CPU, but had already switched to 32nm for the GPU. A full-fledged transition then occurred with the arrival of the chip Apple A6 in 2012, which powered the original iPhone 5. When this change came, the iPhone 5 offered a 30% faster CPU. Anyway, at that time the development of chips was just starting to gain momentum. A relatively fundamental change then came in 2013 with the iPhone 5S, or the chip Apple A7. It was the first ever 64-bit chipset for phones, which was based on the 28nm production process. In just 3 years, Apple managed to reduce it by almost half. Anyway, in terms of CPU and GPU performance, it improved almost twice.

In the following year (2014), he applied for the word iPhone 6 and 6 Plus, in which he visited Apple A8. By the way, this was the very first chipset, the production of which was procured by the aforementioned Taiwanese giant TSMC. This piece came with a 20nm manufacturing process and offered a 25% more powerful CPU and 50% more powerful GPU. For the improved sixes, the iPhone 6S and 6S Plus, the Cupertino giant bet on a chip Apple A9, which is quite interesting in its own way. Its production was ensured by both TSMC and Samsung, but with a fundamental difference in the production process. Although both companies produced the same chip, one company came out with a 16nm process (TSMC) and the other with a 14nm process (Samsung). Despite this, differences in performance did not emerge. There were only rumors among Apple users that iPhones with a Samsung chip discharge faster under more demanding load, which was partially true. In any case, Apple mentioned after the tests that this is a difference in the range of 2 to 3 percent, and therefore has no real impact.

Chip production for iPhone 7 and 7 Plus, Apple A10 Fusion, was placed in the hands of TSMC the following year, which has remained the exclusive producer ever since. The model has practically not changed in terms of the production process, as it was still 16nm. Even so, Apple managed to increase its performance by 40% for the CPU and 50% for the GPU. He was a bit more interesting Apple A11 Bionic in iPhones 8, 8 Plus and X. The latter boasted a 10nm production process and thus saw a relatively fundamental improvement. This was mainly due to the higher number of cores. While the A10 Fusion chip offered a total of 4 CPU cores (2 powerful and 2 economical), the A11 Bionic has 6 of them (2 powerful and 4 economical). The powerful ones received a 25% acceleration, and in the case of economical ones, it was a 70% acceleration.

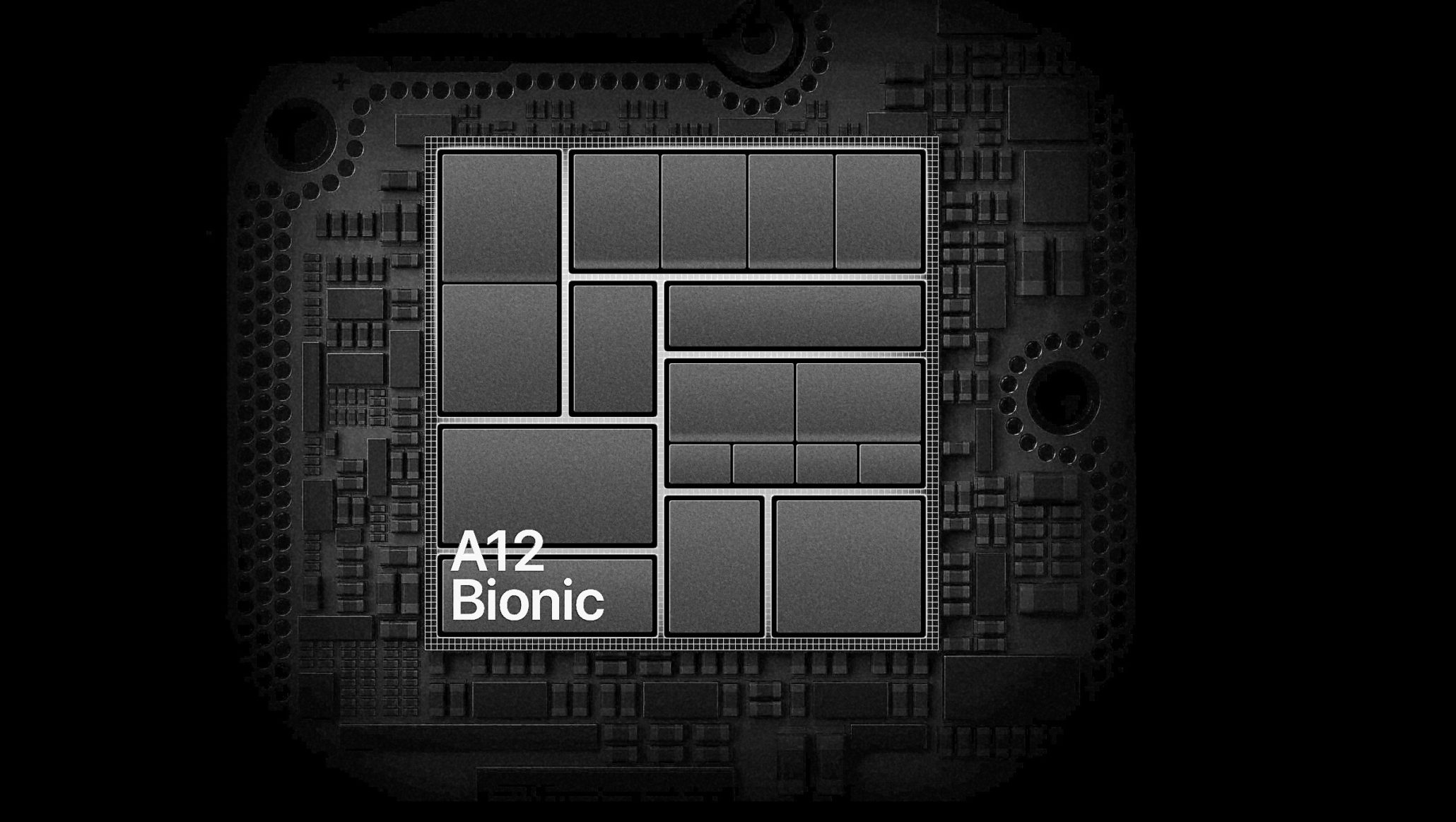

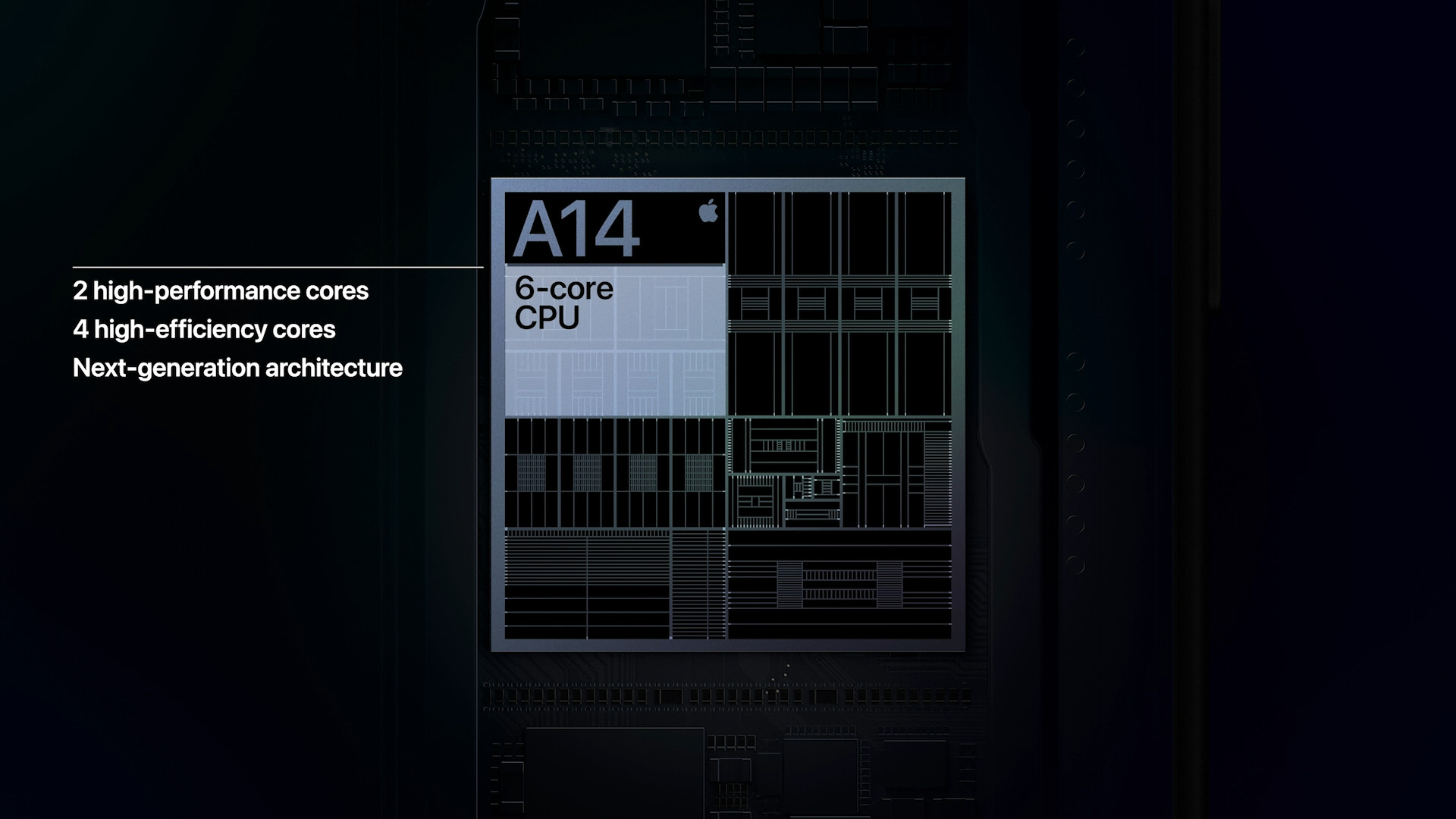

The Cupertino giant subsequently drew world attention to itself in 2018 with the chip Apple A12 Bionic, which became the first ever chipset with a 7nm manufacturing process. The model specifically powers the iPhone XS, XS Max, XR, as well as the iPad Air 3, iPad mini 5 or iPad 8. Its two powerful cores are 11% faster and 15% more economical compared to the A50 Bionic, while the four economical cores consume 50% less power than the previous chip. The Apple chip was then built on the same production process A13 Bionic intended for iPhone 11, 11 Pro, 11 Pro Max, SE 2 and iPad 9. Its powerful cores were 20% faster and 30% more economical, while the economical one received 20% acceleration and 40% more economy. He then opened the current era Apple A14 Bionic. It first went to the iPad Air 4 and a month later appeared in the iPhone 12 generation. At the same time, it was the very first commercially sold device that offered a chipset based on the 5nm production process. In terms of CPU, it improved by 40% and in GPU by 30%. We are currently offered the iPhone 13 with a chip Apple A15 Bionic, which is again based on the 5nm production process. Chips from the M-Series family, among others, rely on the same process. Apple deploys them in Macs with Apple Silicon.

What the future will bring

In the fall, Apple should present us with a new generation of Apple phones, the iPhone 14. According to current leaks and speculations, the Pro and Pro Max models will boast a completely new Apple A16 chip, which could theoretically come with a 4nm manufacturing process. At least this has been talked about for a long time among apple growers, but the latest leaks refute this change. Apparently, we will "only" see an improved 5nm process from TSMC, which will ensure 10% better performance and power consumption. The change should therefore come only in the following year. In this direction, there is also talk of using a completely revolutionary 3nm process, on which TSMC works directly with Apple. However, the performance of mobile chipsets has reached a literally unimaginable level in recent years, making minor progress literally negligible.

It could be interest you

Flying around the world with Apple

Flying around the world with Apple