Leander Kahney's book, describing the life and career of Tim Cook, is published in a few days. The work was originally supposed to be much more comprehensive and included details related to Steve Jobs. Some of the content didn't make it into the book, but Kahney shared it with the site's readers Cult of Mac.

Locally and perfectly

Steve Jobs was known as a perfectionist who liked to have everything under control - computer manufacturing was no exception in this regard. When he founded NeXT after leaving Apple in the mid-1980s, he wanted to perfectly control and control production. But he soon found out that it would not be easy. Leander Kahney, the author of Tim Cook's biography, offers an interesting insight into the behind-the-scenes operation of Jobs' NeXT.

In his "Steve Jobs and the NeXT Big Thing", Randall E. Stross unscrupulously called the local production of NeXT computers "the most expensive and least smart undertaking Jobs ever made". In the one year that NeXT ran its own computer factory, it lost both cash and public interest.

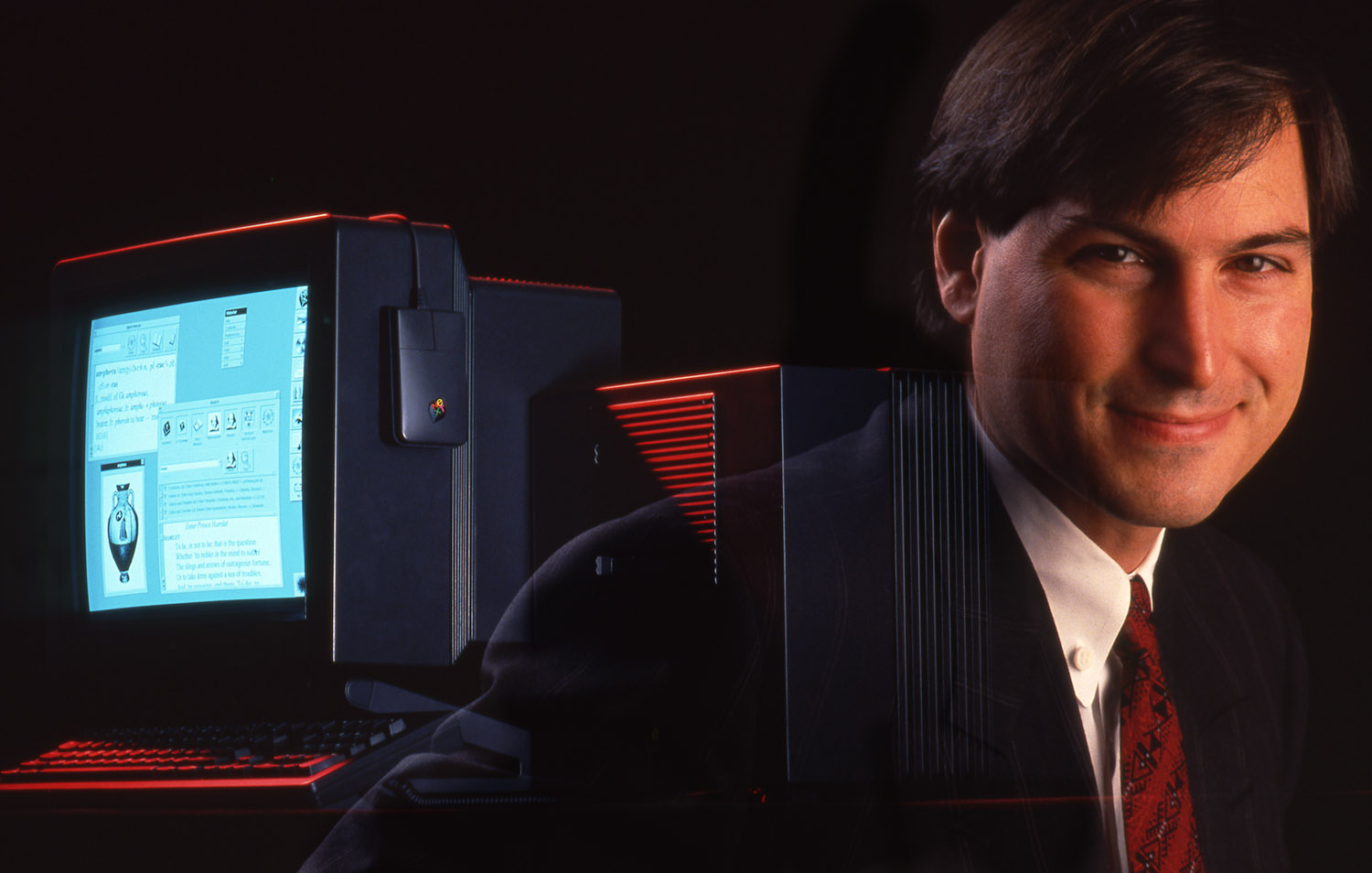

Making his own computers was something that Jobs pursued from the very beginning. In the early days of NeXT's operations, Jobs had a fairly sober plan in which some of the manufacturing would be handled by contractors, while NeXT itself would handle the final assembly and testing. But in 1986, Jobs's perfectionism and desire for perfect control won out, and he decided that his company would eventually take over the entire automated production of its own computers. It was supposed to take place directly on the territory of the United States.

The factory premises were located in Fremont, California and spread over 40 thousand square feet. The factory was located not far from where Macintoshes were made just a few years ago. Jobs reportedly joked with NeXT CFO Susan Barnes that he had learned from the mistakes of starting automated manufacturing for Apple so that the NeXT factory should run smoothly.

The right shade, the right direction, and no hangers

Part of the work in said factory was done by robots, assembling printed circuit boards for computers from NeXTU using technology that is currently common in most factories around the world. As with the Macintosh, Jobs wanted to be in control of everything - including the color scheme of the machines in the factory, which were carried in precisely defined shades of grey, white and black. Jobs was strict about the shades of the machines, and when one of them arrived in a slightly different color, Steve had it returned without further ado.

Jobs' perfectionism manifested itself in other directions as well - for example, he demanded that the machines proceed from right to left when assembling boards, which was the opposite direction than was usual at the time. The reason was, among other things, that Jobs wanted to make the factory accessible to the public, and the public, in his opinion, had the right to watch the entire process so that it was as pleasant as possible from their point of view.

In the end, however, the factory was not made publicly available, so this step turned out to be very costly and fruitless.

But this was not the only step in the interest of making the factory accessible to potential visitors - Jobs, for example, had a special staircase installed here, white walls in a gallery style or perhaps luxurious leather armchairs in the lobby, one of which cost 20 thousand dollars. By the way, the factory lacked hangers where employees could put their coats - Jobs was afraid that their presence would disturb the minimalist look of the interiors.

Touching propaganda

Jobs never disclosed the cost of building the factory, but it is speculated to be "significantly less" than the $20 million it took to build the Macintosh factory.

The manufacturing technology was demonstrated by NeXT in a short film called "The Machine That Builds Machines". In the film, robots "acted" working with records to the sounds of music. It was almost a propaganda picture, showing all the possibilities that the NeXT factory had to offer. An article in Newsweek magazine from October 1988 even describes how Jobs was almost moved to tears by the sight of working robots.

A slightly different factory

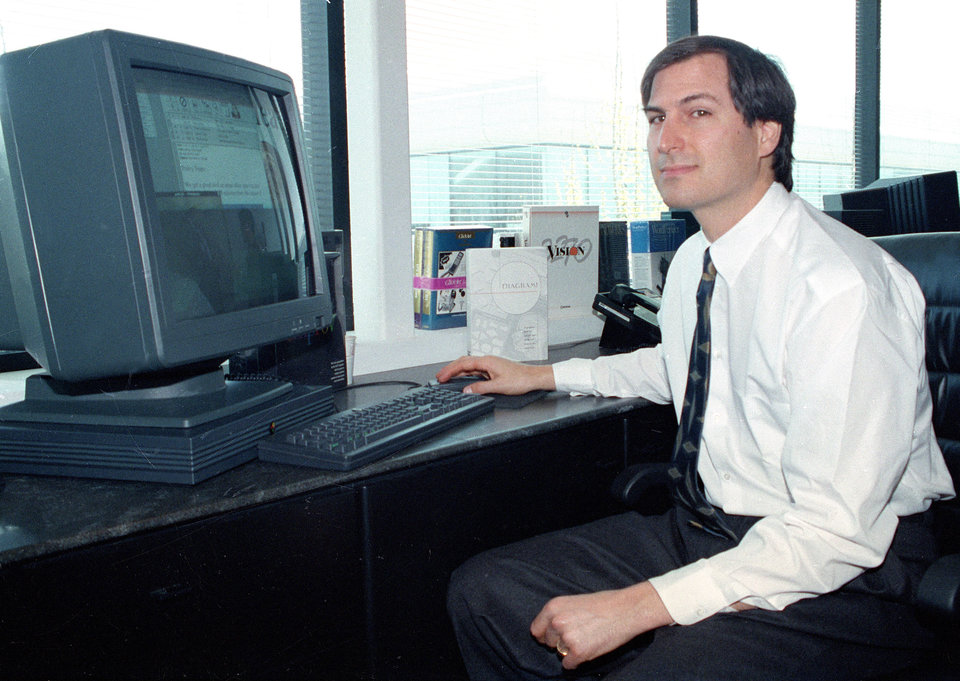

Fortune magazine described NeXT's manufacturing facility as "the ultimate computer factory," featuring just about everything—lasers, robots, speed, and surprisingly few defects. An admirable article describes, for example, a robot with the appearance of a sewing machine that assembles integrated circuits at tremendous speed. The extensive description ends with a statement of how the robots have largely surpassed human power in the factory. At the end of the article, Fortune quotes Steve Jobs - he said at the time that he was "as proud of the factory as he was of the computer".

NeXT did not set any production targets for its factory, but according to estimates at the time, the production line was capable of churning out more than 207 completed boards per year. In addition, the factory had space for a second line, which could double the production volume. But NeXT never reached these numbers.

Jobs wanted his own automated production for two main reasons. The first was secrecy, which would be significantly more difficult to achieve when the production was transferred to a partner company. The second was quality control—Jobs believed that increasing automation would reduce the likelihood of manufacturing defects.

Due to the high degree of automation, the NeXT brand computer factory was quite different from other Silicon Valley manufacturing plants. Instead of "blue-collar" workers, workers with various degrees of technical higher education were employed here - according to available data, up to 70% of the factory's employees had a PhD degree.

Willy Jobs Wonka

Like Willy Wonka, the factory owner from Roald Dahl's book "Dwarf and the Chocolate Factory", Steve Jobs wanted to ensure that his products were not touched by human hands until they reached their owners. After all, Jobs also styled himself in the role of Willy Wonka a few years later, when in his characteristic suit he was escorting the millionth customer who bought an iMac around the Apple campus.

Randy Heffner, vice president of manufacturing whom Jobs lured to NeXT from Hewlett-Packard, described the company's manufacturing strategy as "a conscious effort to produce competitively through effective inventory management of assets, capital, and people." In his own words, he joined NeXT precisely because of its production. The advantages of automated production at NeXT were primarily characterized by Heffner's high quality or low rate of defects.

Where they went wrong?

As brilliant as Jobs' idea for automated manufacturing was, the practice ultimately failed. One of the reasons for the production failure was finance - by the end of 1988, NeXT was producing 400 computers per month to meet demand. According to Heffner, the factory had the capacity to produce 10 units per month, but Jobs was concerned about the possible accumulation of unsold pieces. Over time, production dropped to less than a hundred computers per month.

The production costs were disproportionately high in the context of computers actually sold. The factory was in operation until February 1993, when Jobs decided to say goodbye to his dream of automated production. Along with the closure of the factory, Jobs also definitively said goodbye to the pursuit of his own production.