In general, we are more used to the fact that the bigger something is, the better it is. But this ratio does not apply in the case of the production technology of processors and chips, because here it is exactly the opposite. Even if, with regard to performance, we can at least deviate a little from the nanometer number, it is still primarily a matter of marketing.

The abbreviation "nm" here stands for nanometer and is a unit of length that is 1 billionth of a meter and is used to express dimensions on an atomic scale - for example, the distance between atoms in solids. In technical terminology, however, it typically refers to a "process node". It is used to measure the distance between adjacent transistors in the design of processors and to measure the actual size of these transistors. Many chipset companies such as TSMC, Samsung, Intel, etc. use nanometer units in their manufacturing processes. This indicates how many transistors are inside the processor.

It could be interest you

Why less nm is better

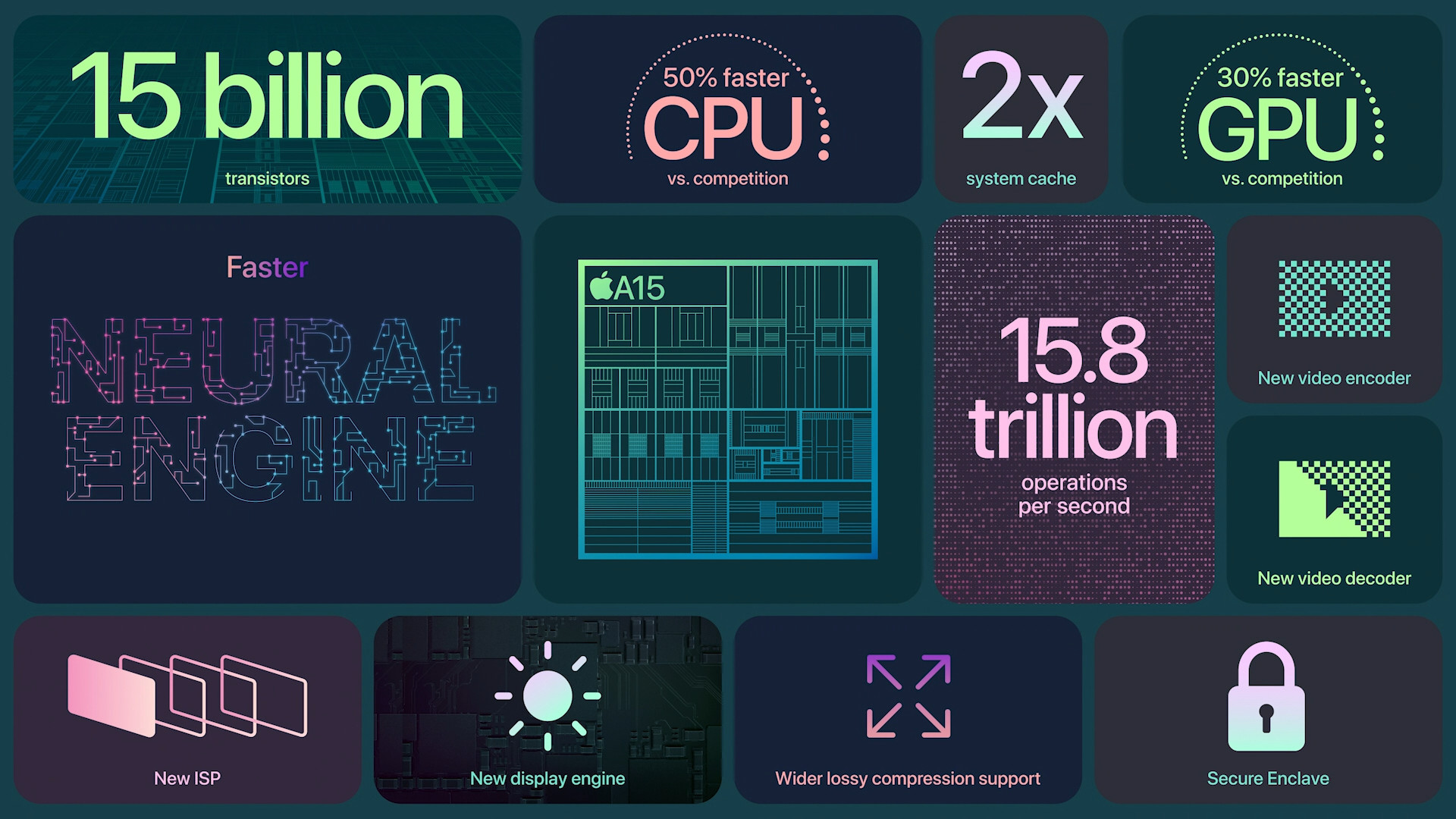

Processors consist of billions of transistors and are housed in a single chip. The smaller the distance between the transistors (expressed in nm), the more they can fit in a given space. As a result, the distance the electrons travel to do work is shortened. This results in faster computing performance, less power consumption, less heating and a smaller size of the matrix itself, which ultimately paradoxically reduces costs.

However, it should be noted that there is no universal standard for any calculation of a nanometer value. Therefore, different processor manufacturers also calculate it in different ways. It means TSMC's 10nm is not equivalent to Intel's 10nm and Samsung's 10nm. For that reason, determining the number of nm is to some extent just a marketing number.

The present and the future

Apple uses the A13 Bionic chip in its iPhone 3 series, the iPhone SE 6rd generation but also the iPad mini 15th generation, which is made with a 5nm process, just like the Google Tensor used in the Pixel 6. Their direct competitors are Qualcomm's Snapdragon 8 Gen 1 , which is manufactured using a 4nm process, and then there is Samsung's Exynos 2200, which is also 4nm. However, it should be taken into account that apart from the nanometer number, there are other factors that affect the performance of the device, such as the amount of RAM memory, the graphics unit used, the storage speed, etc.

It is expected that this year's A16 Bionic, which will be the heart of the iPhone 14, will also be manufactured using the 4nm process. Commercial mass production using the 3nm process should not start until the fall of this year or the beginning of next year. Logically, the 2nm process will then follow, which IBM has already announced, according to which it provides 45% higher performance and 75% lower power consumption than the 7nm design. But the announcement does not yet mean mass production.

It could be interest you

The next development of the chip can be photonics, in which small packets of light (photons) will move instead of electrons traveling along silicon paths, increasing speed and, of course, taming energy consumption. But for now it's just the music of the future. After all, today the manufacturers themselves often equip their devices with such powerful processors that they cannot even use their full potential and to some extent also tame their performance with various software tricks.

Adam Kos

Adam Kos