Towards the end of last week, future plans and projections of the Taiwanese giant TSMC, which manufactures processors for Apple (but also for many other companies), began to appear on the web. As it seems, the implementation of more modern production technology will still take some time, which means that we will see the crossing of the next technical milestone in two years (and that in the most optimistic case).

It could be interest you

Since 2013, the giant TSMC has been the exclusive manufacturer of processors for Apple's mobile products, and given the information from the last week, when the company announced an investment of 25 billion dollars to implement a more advanced manufacturing process, it does not look like anything should change in this relationship. However, additional information emerged over the weekend that outlines how complex the implementation of the new manufacturing process is.

The CEO of TMSC announced that large-scale and commercial production of processors on the 5nm production process will not begin until the turn of 2019 and 2020. The first iPhones and iPads with these processors will thus appear in the fall of 2020 at the earliest, i.e. in more than two years. Until then, Apple will have to "just" make do with the current 7nm manufacturing process for its designs. It should thus be up-to-date for two generations of devices, which is usual according to developments in recent years.

It could be interest you

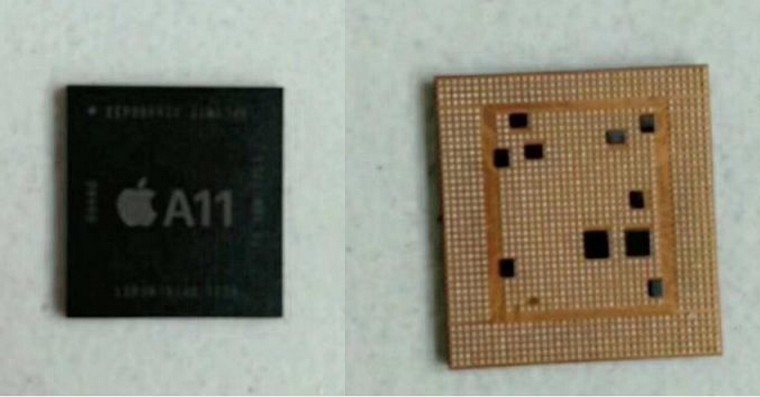

The current generations of iPhones and iPad Pro have A11 and A10X processors, which were manufactured using the 10nm manufacturing process. The predecessor in the form of the 16nm production process also lasted two generations of iPhones and iPads (6S, SE, 7). This year's novelties should see the transition to a more modern, 7nm production process, both in the case of new iPhones and in the case of new iPads (Apple should present both novelties by the end of the year). This production process was also to be used in the case of new products arriving next year.

The transition to a new production process brings with it many advantages for the end user, but also a lot of worries for the manufacturer, because the transition and transfer of production is a very expensive and demanding process. The first chips made on the 5nm production process may arrive as early as next year. However, there is a period of at least half a year during which the production is fine-tuned and the necessary modifications are made. In this mode, factories are only able to produce chips with simple architectures and not yet in a completely reliable design. Apple would definitely not risk the quality of its chips and will send its processors to production at the moment when everything is tuned to perfection. Thanks to this, we will most likely not see new chips made with the 5nm process until 2020. But what does this mean in practice for users?

It could be interest you

In general, the transition to a more modern production process brings higher performance and lower consumption (either to a limited extent collectively or to a greater extent individually). Thanks to a more advanced manufacturing process, it is possible to fit significantly more transistors into the processor, which will be able to perform calculations and fulfill the "tasks" assigned to them by the system. New designs usually also come with new technologies, such as the machine learning elements that Apple has integrated into the A11 Bionic processor design. Currently, Apple is many miles ahead of the competition when it comes to processor design. Given that TSMC is at the cutting edge of chip manufacturing, it is unlikely that anyone will surpass Apple in this regard in the near future. The onset of new technologies may thus be slower than expected (the stop at 7nm was supposed to be a one-generation affair), but Apple's position should not change and the processors in iPhones and iPads should continue to be the best available on the mobile platform.

Source: Appleinsider