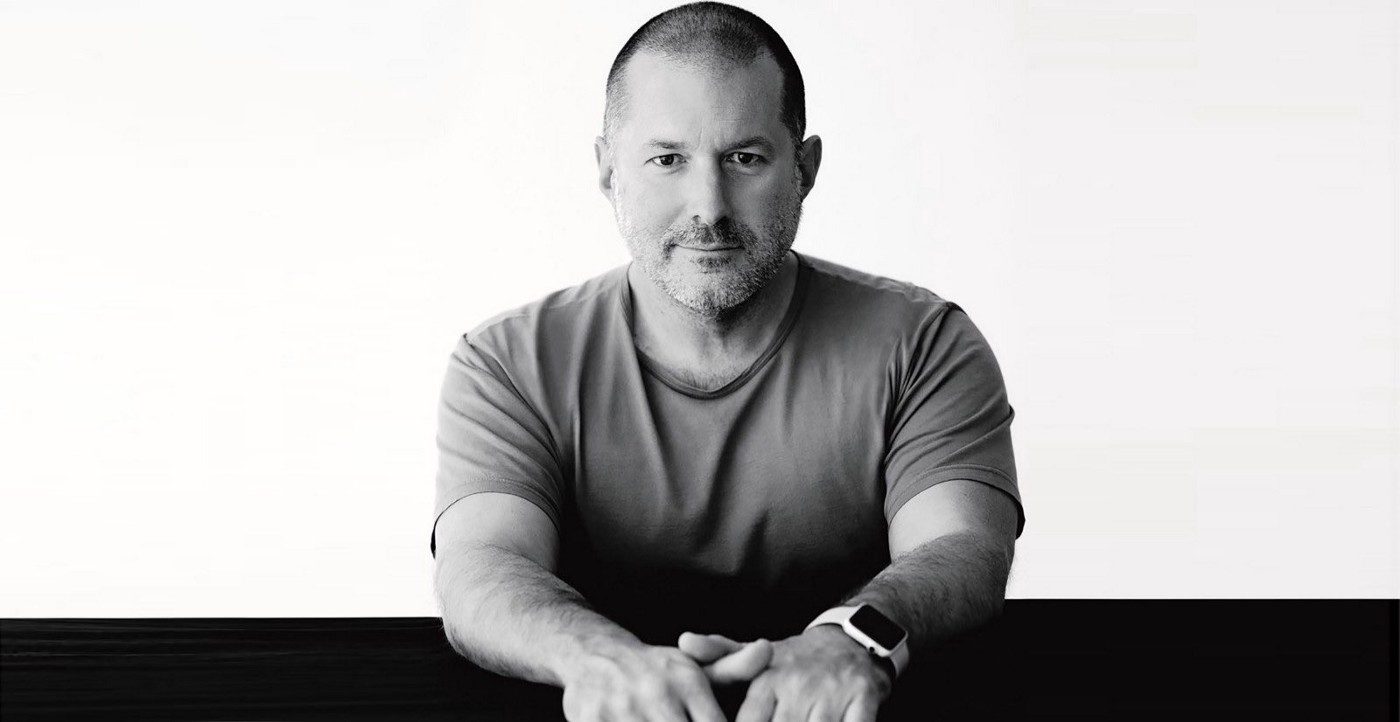

With the introduction of the new MacBook Pros, there is a lot of talk about the fact that this is the first Apple product created without the design signature of Jonathan Ivo. If that was indeed the case, it would have taken him a maximum of two years from development to sale. Ive left Apple on November 30, 2019.

Apple's product development process may be one of the most successful design processes ever implemented. That's because its market capitalization now stands at roughly two trillion dollars, making Apple the most valuable publicly traded company in the world. But he carefully protects his business.

It could be interest you

Back when Steve Jobs was still at the company, it would have been nearly impossible to figure out its inner workings. However, this may not be surprising when you consider that the company's market advantage is its design approach to its products. It pays off to keep everything that those around you don't necessarily know under wraps.

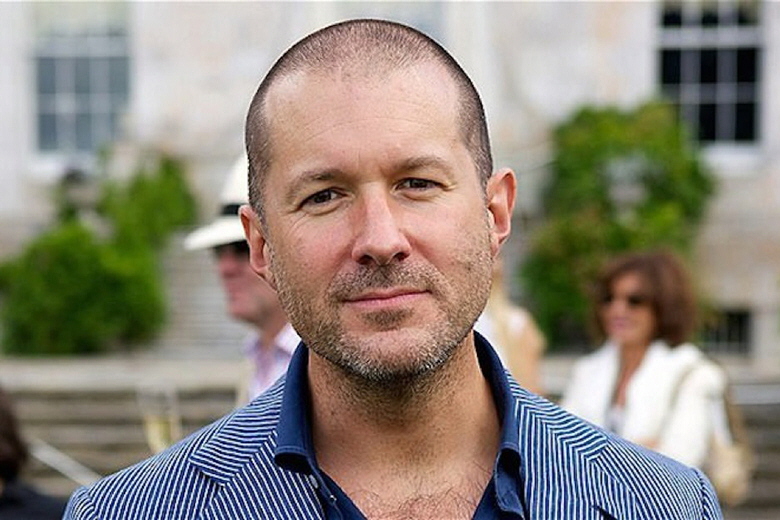

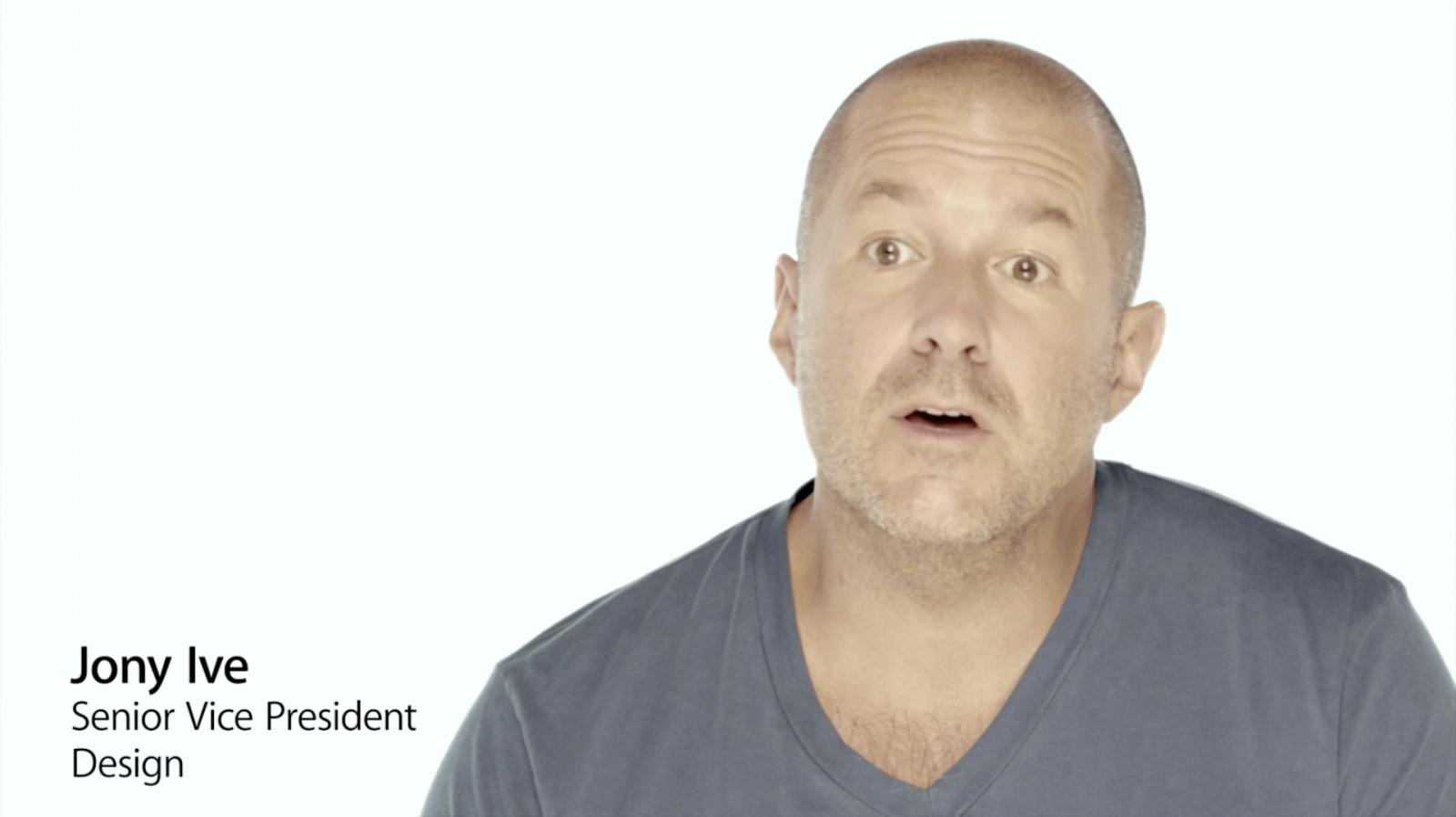

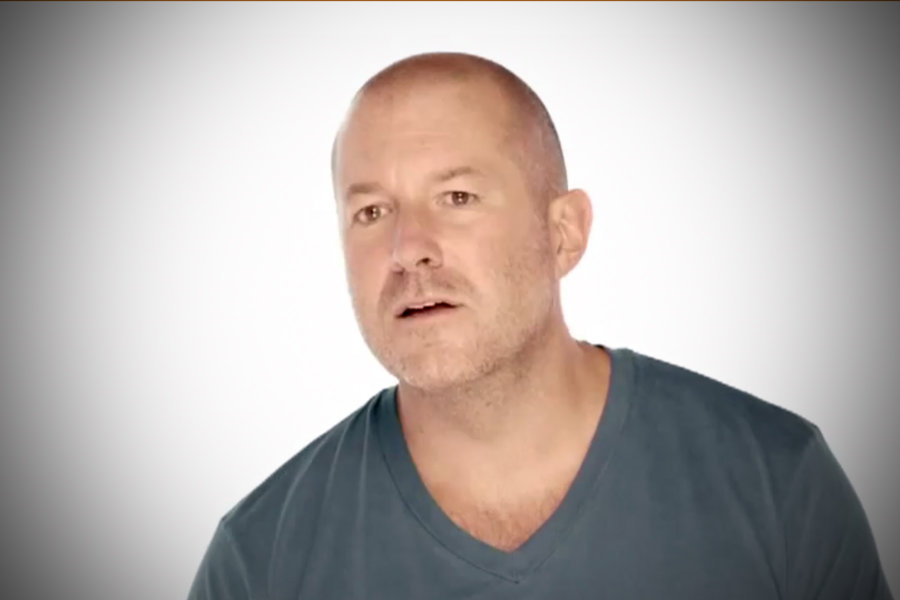

Jony Ive

At Apple, design is at the fore, something Jony Ive stated when he worked at the company. Neither he nor his design team were subject to financial, production or other restrictions. Their completely free hand could thus determine not only the amount of the budget, but also ignoring any production procedures. The only thing that mattered was that the product was perfect in design. And this simple concept turned out to be very successful.

Separate work

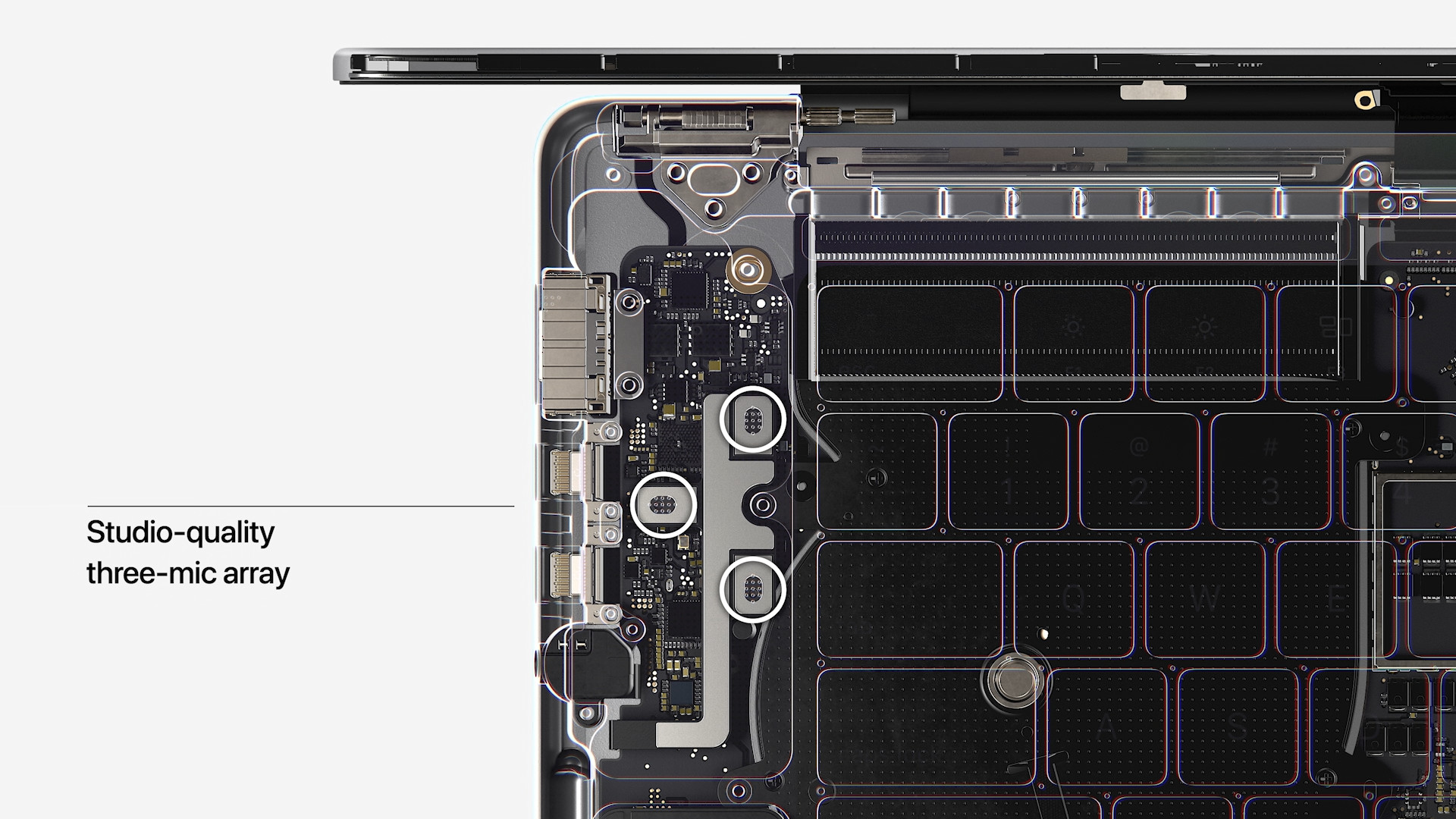

When a design team works on a new product, they are completely cut off from the rest of the company. There are even physical controls in place to prevent the team from interacting with other Apple employees during the day. The team itself is also removed from Apple's traditional hierarchy at this point, creating its own reporting structures and being accountable to itself. But thanks to this, he can fully concentrate on his work rather than on the daily duties of an ordinary employee.

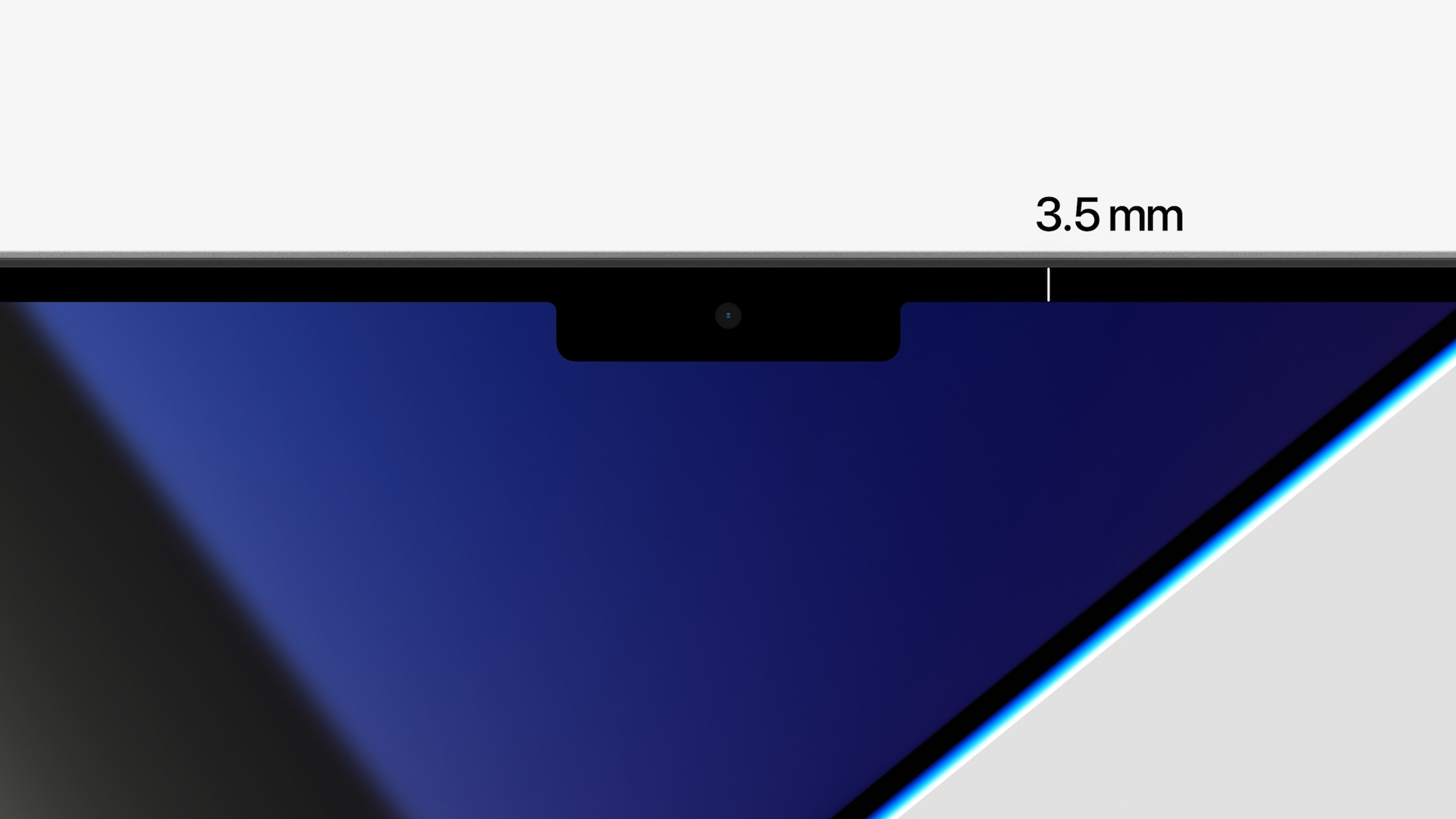

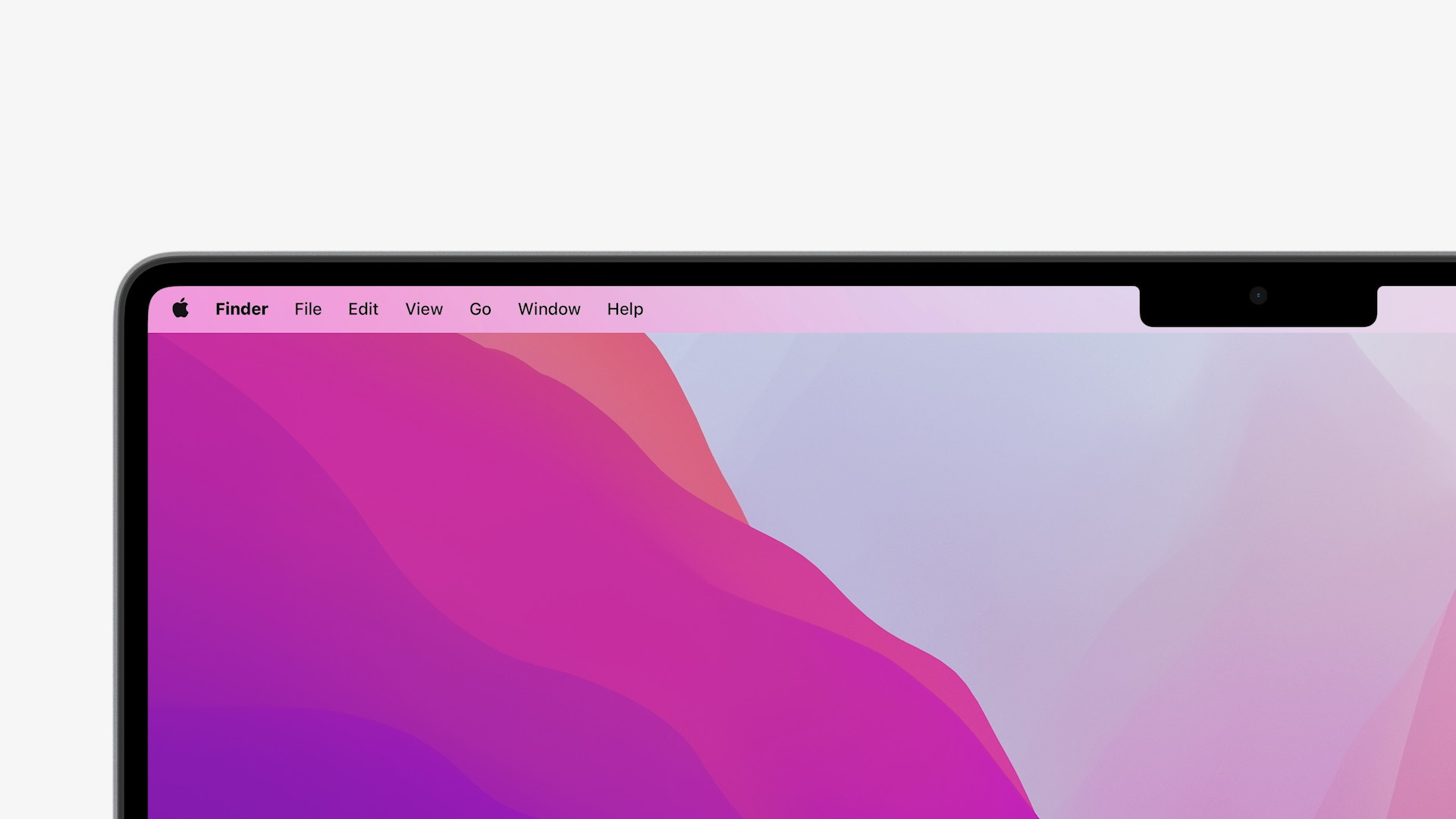

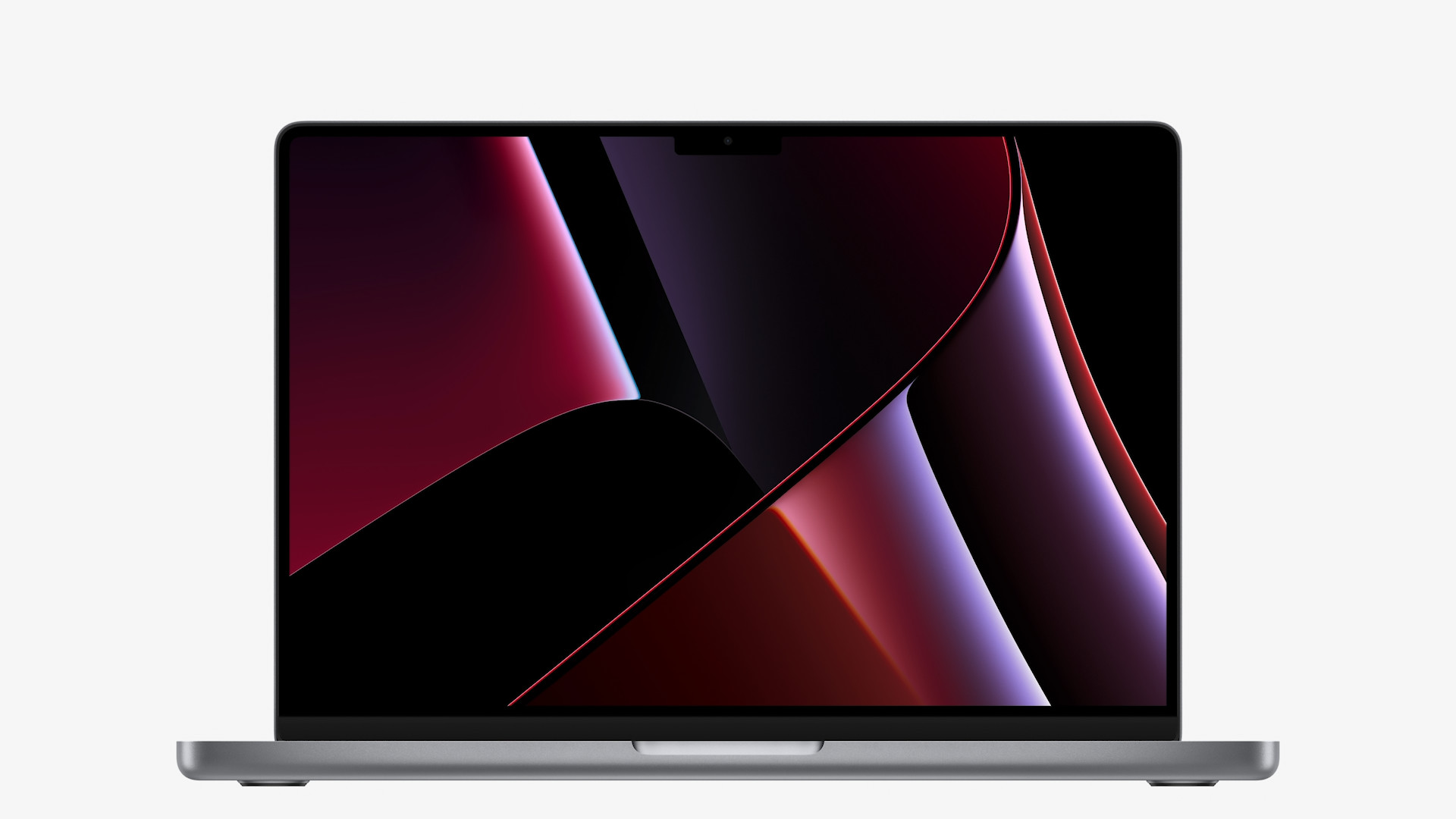

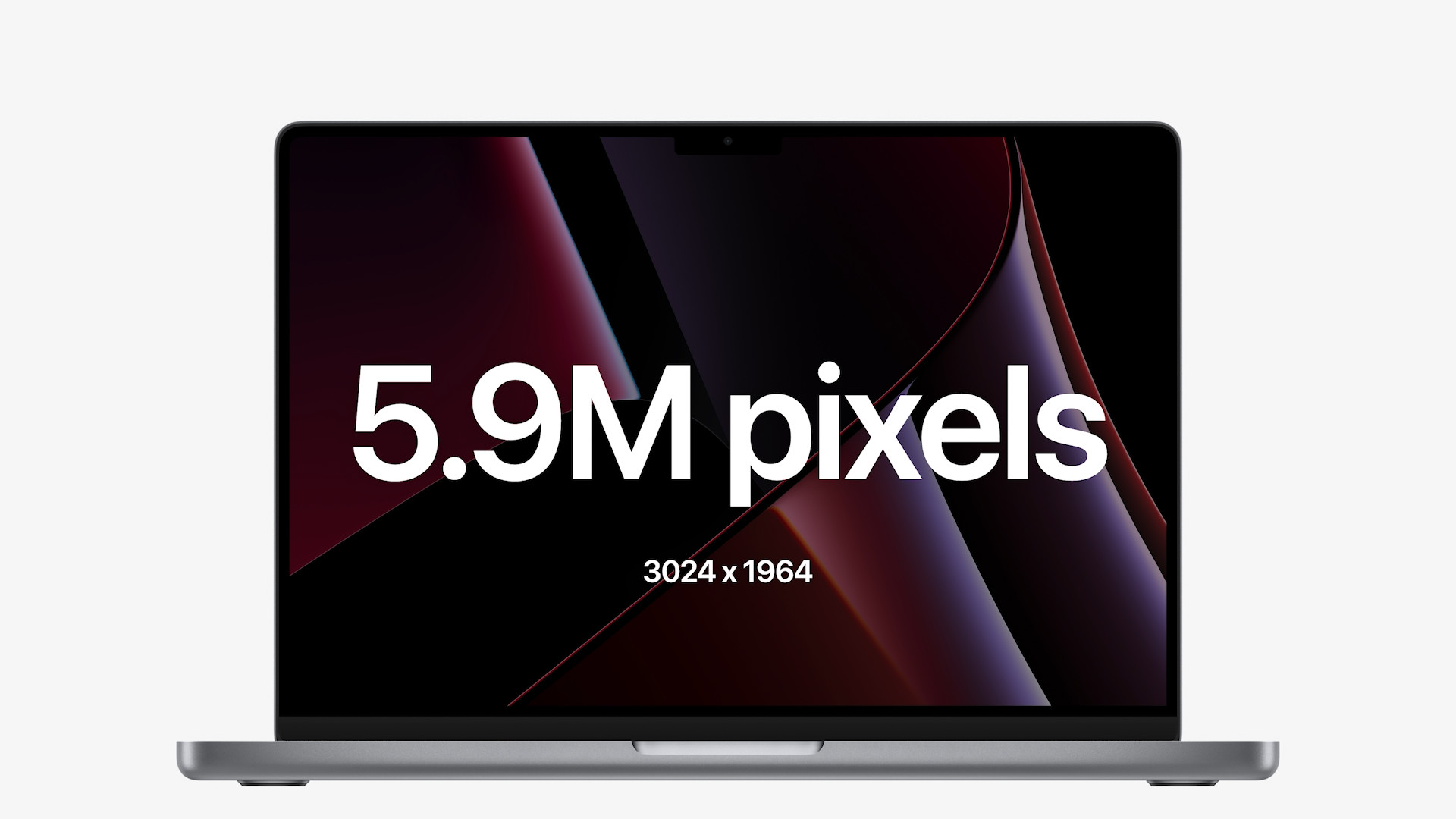

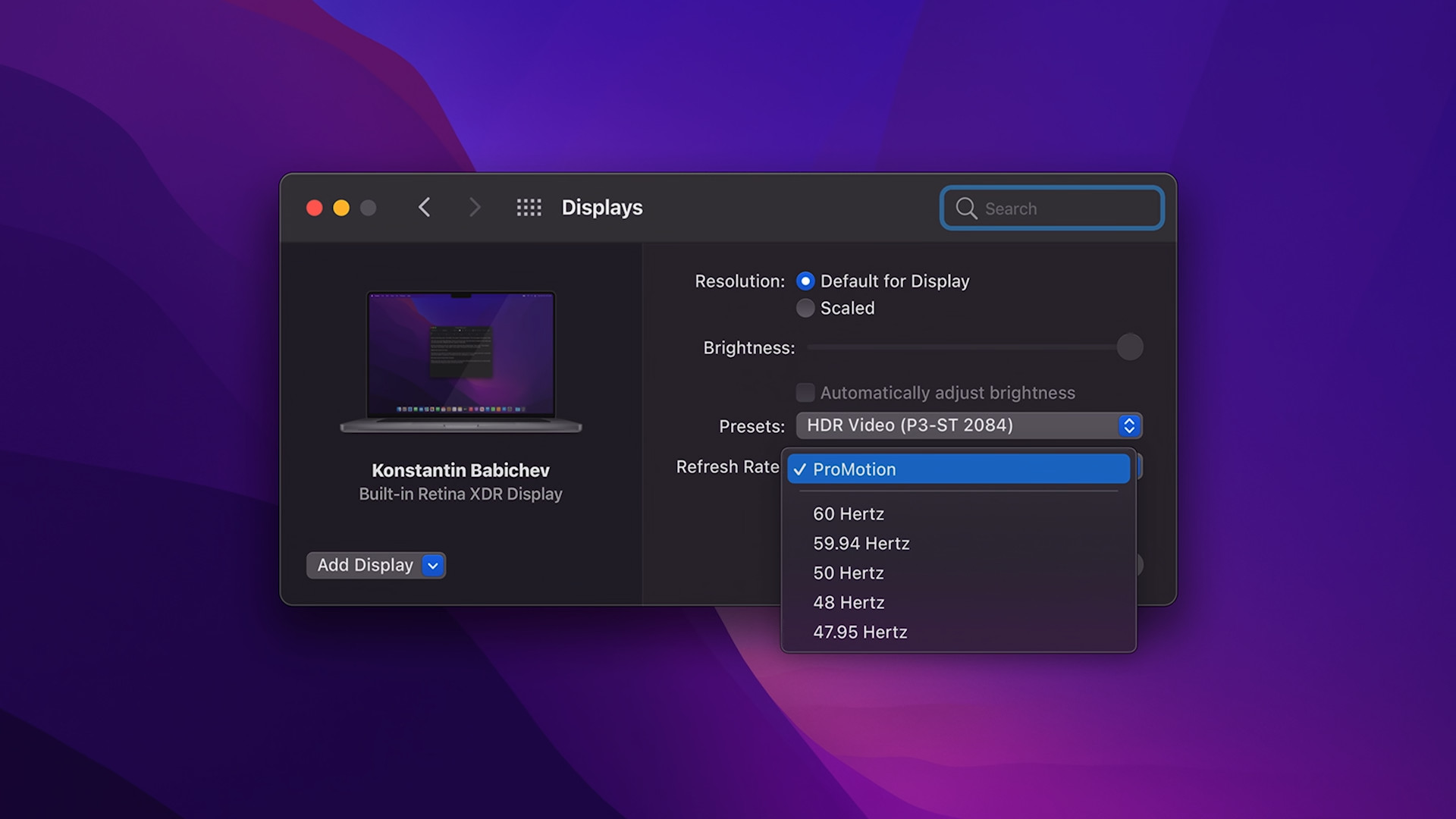

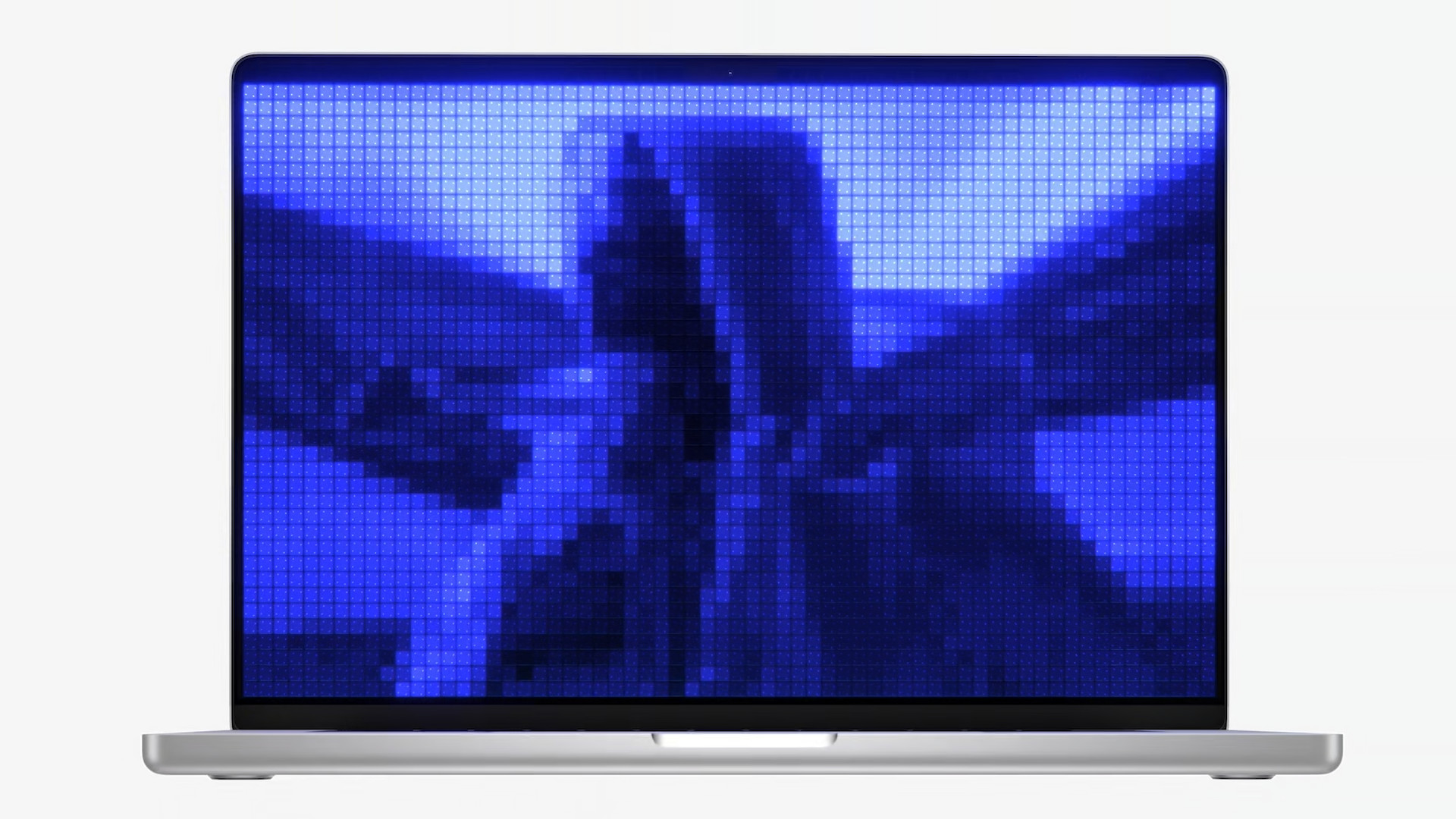

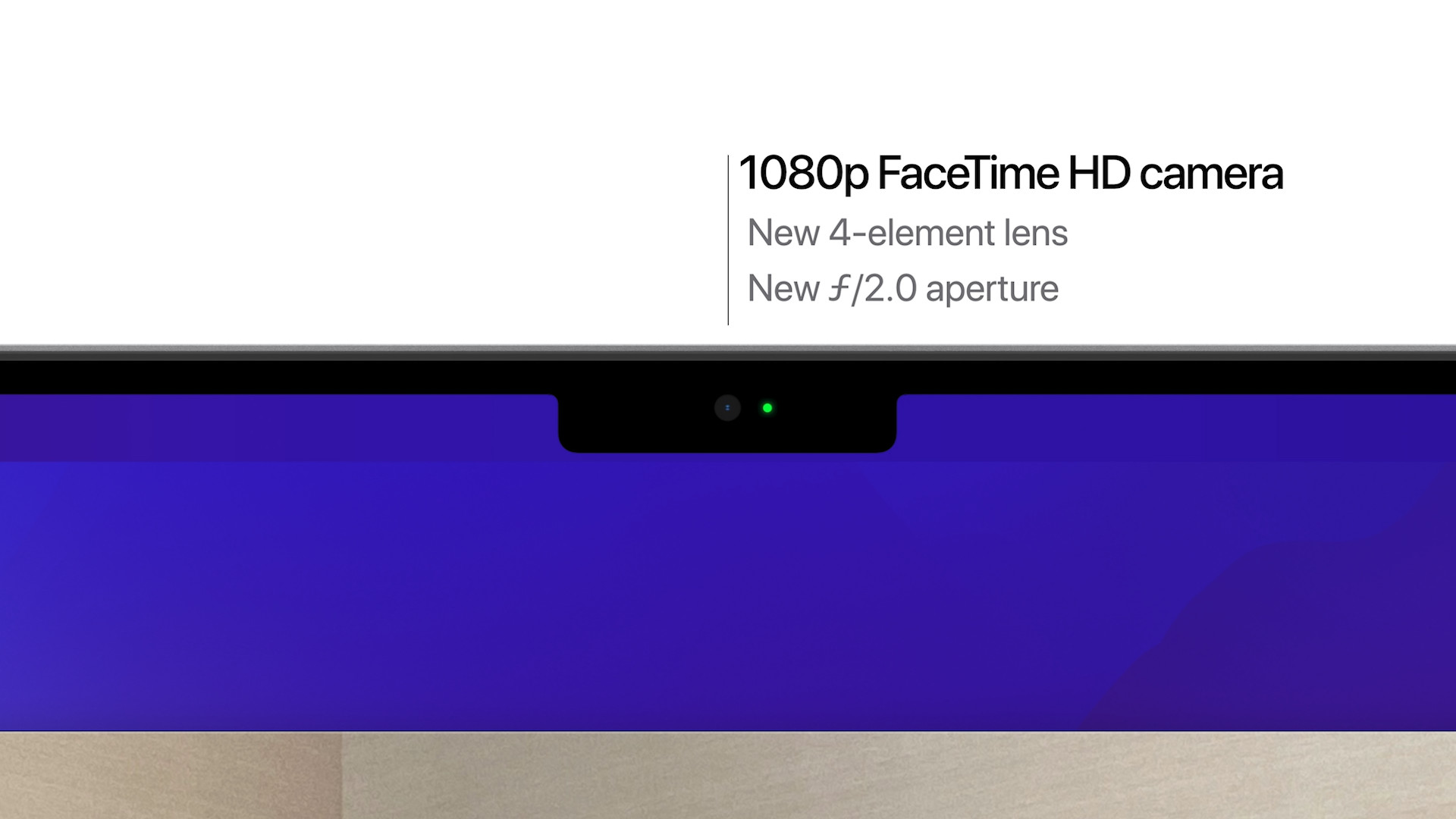

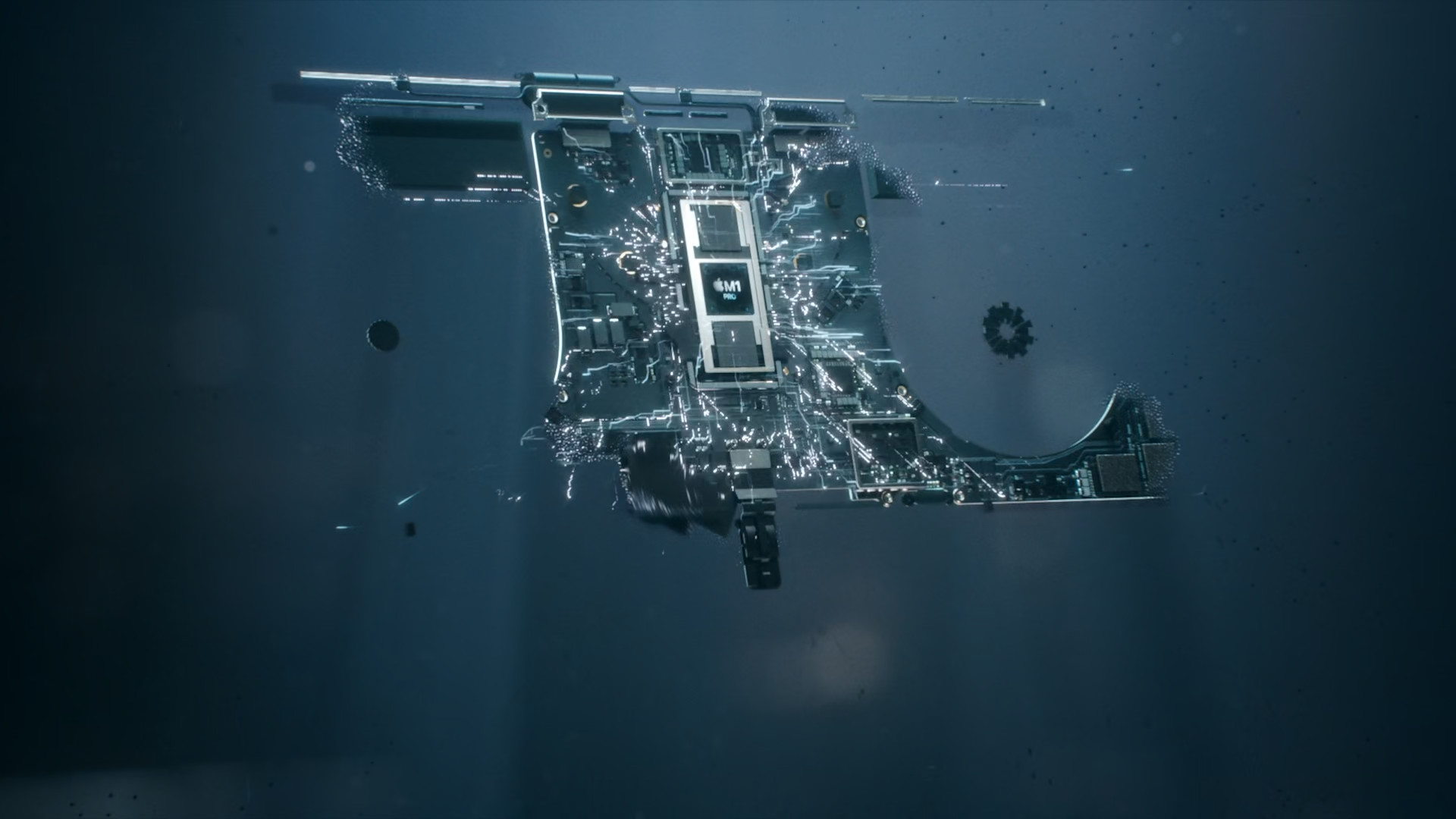

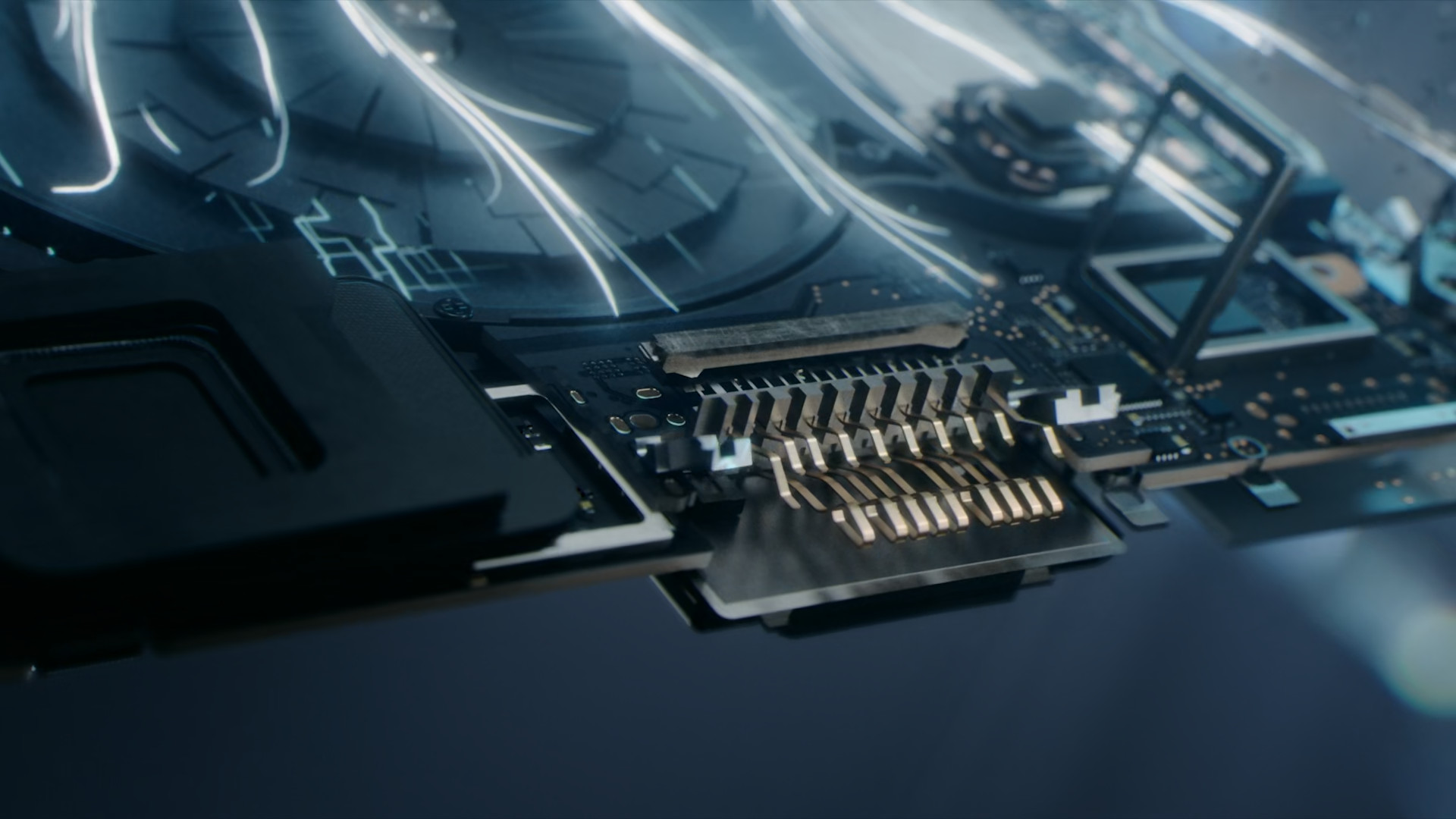

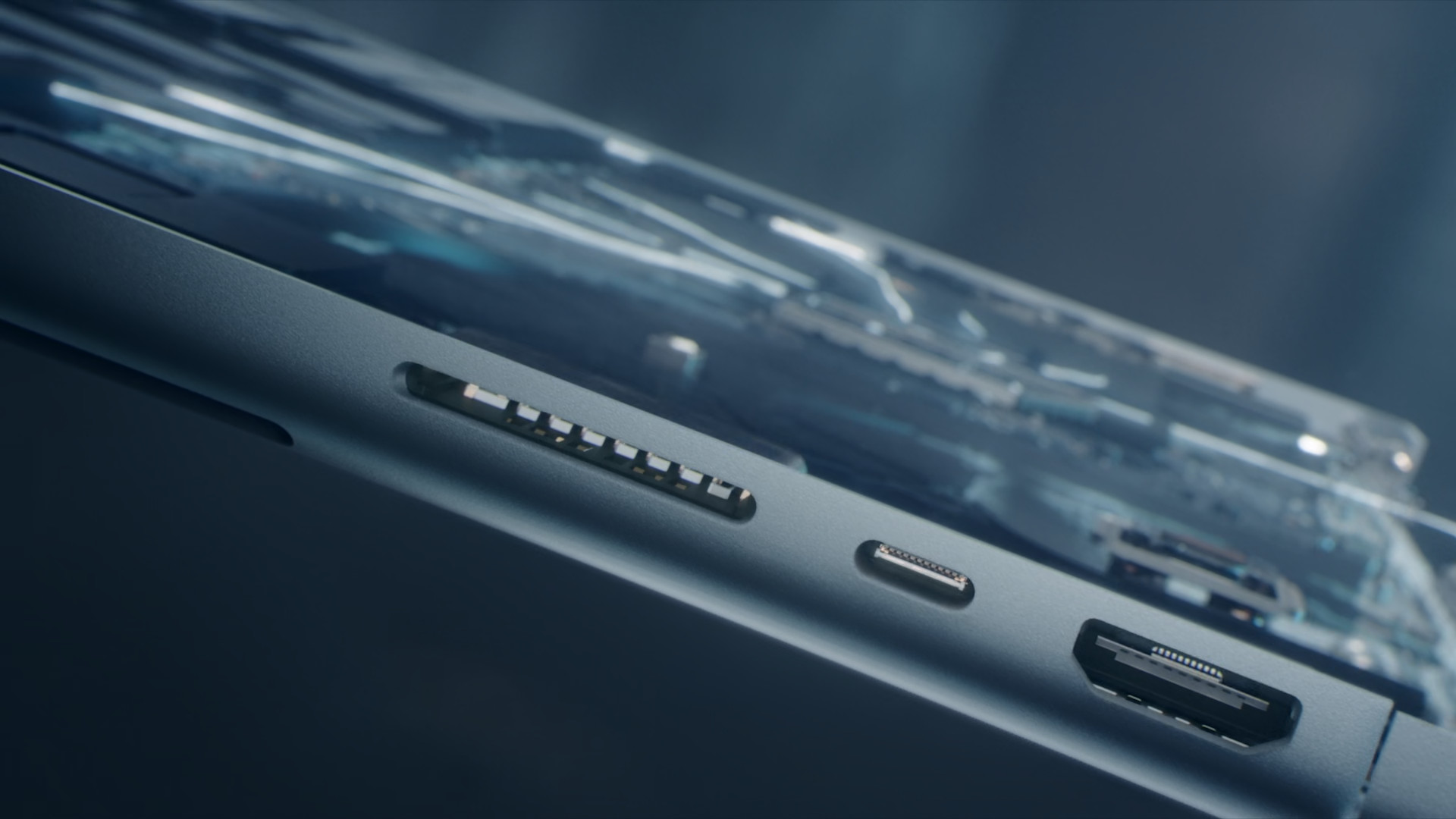

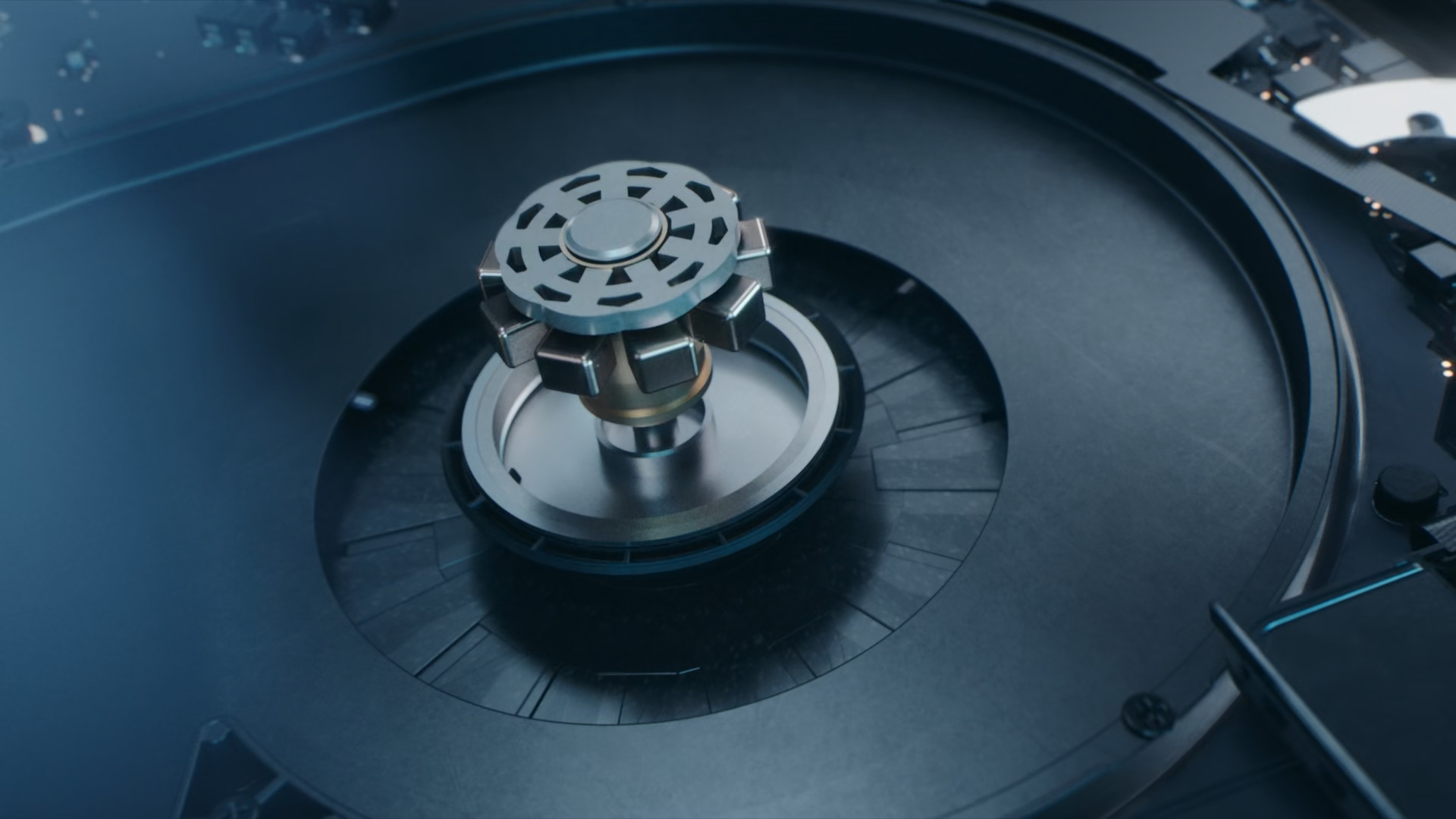

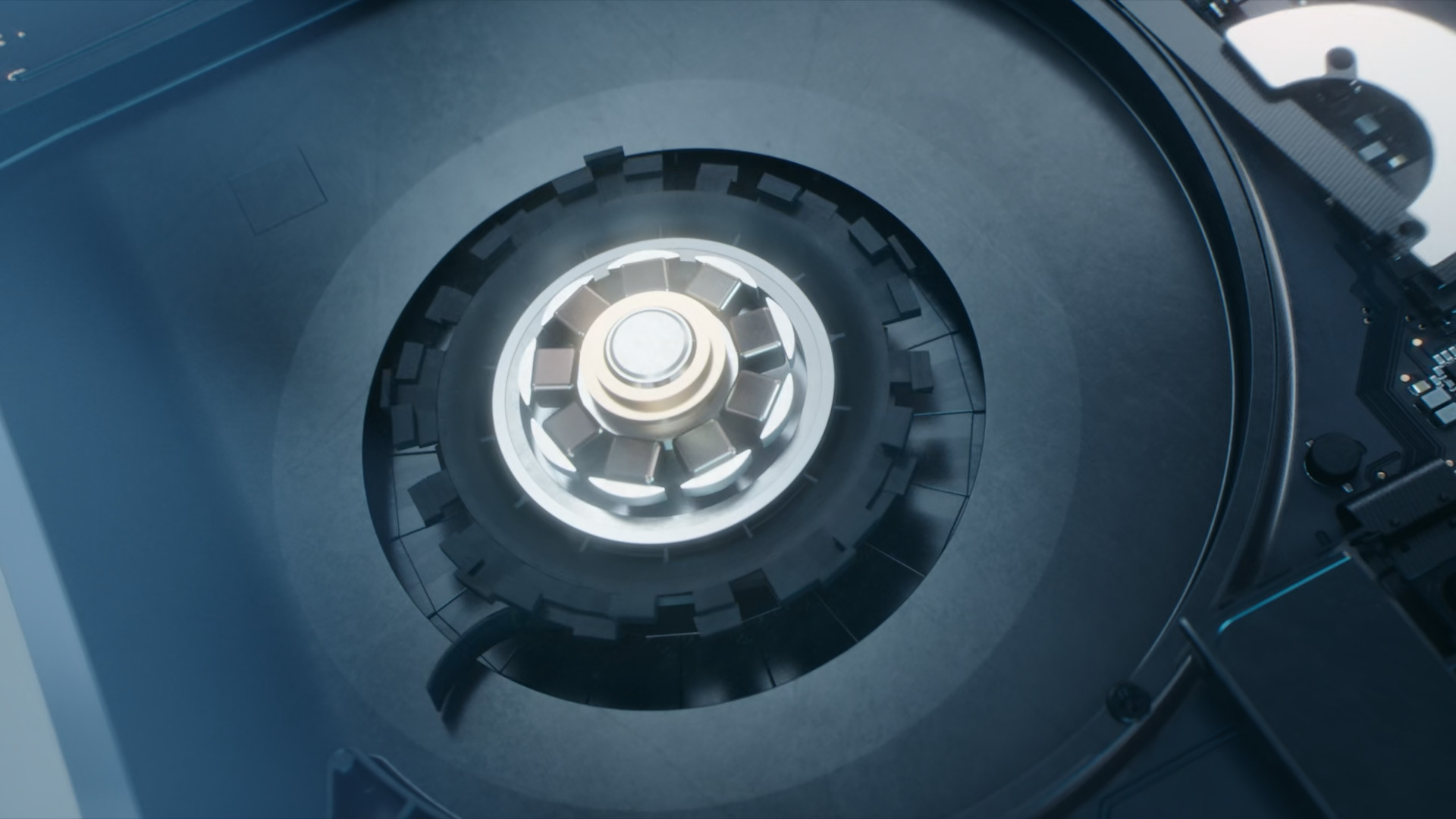

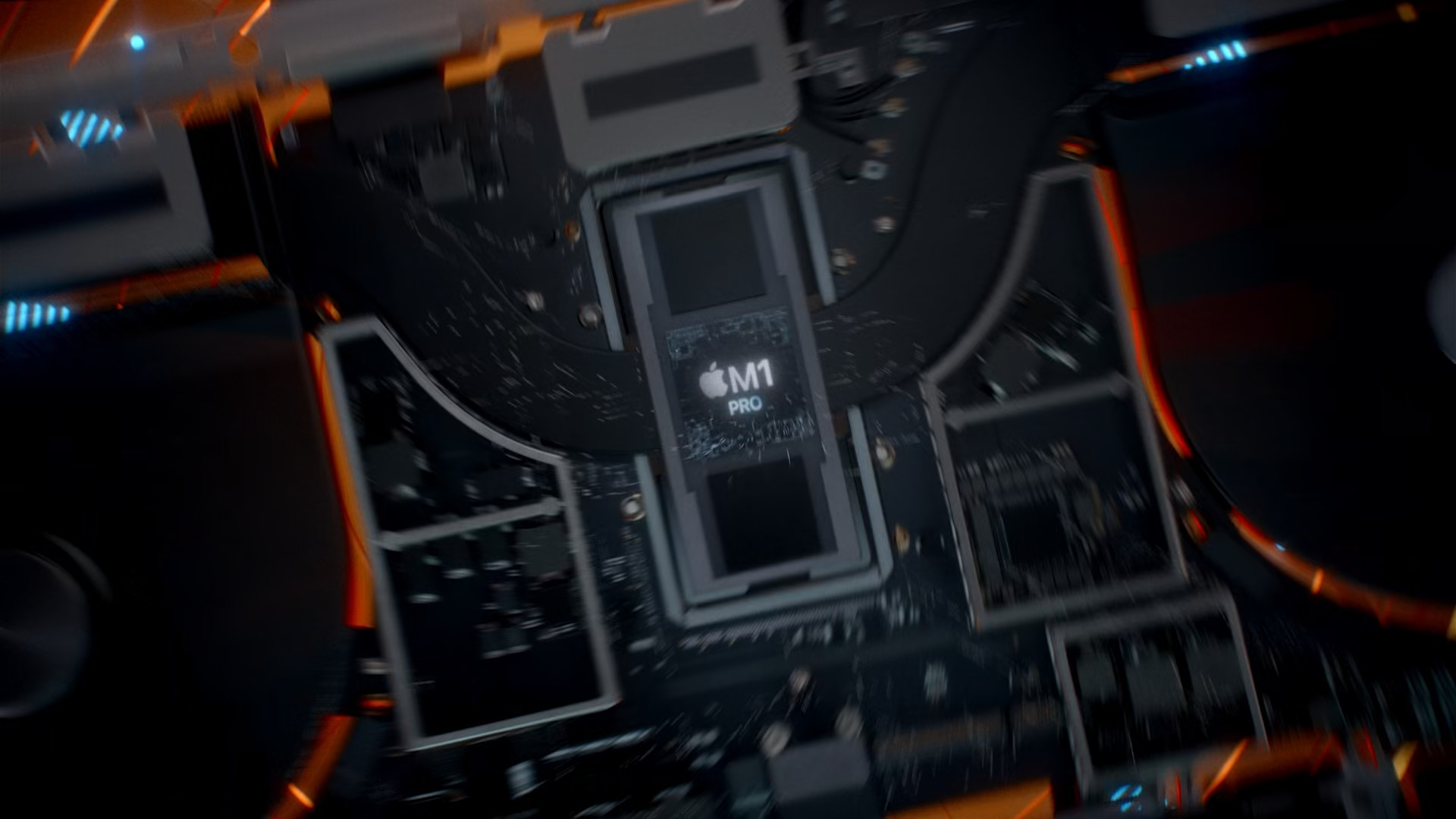

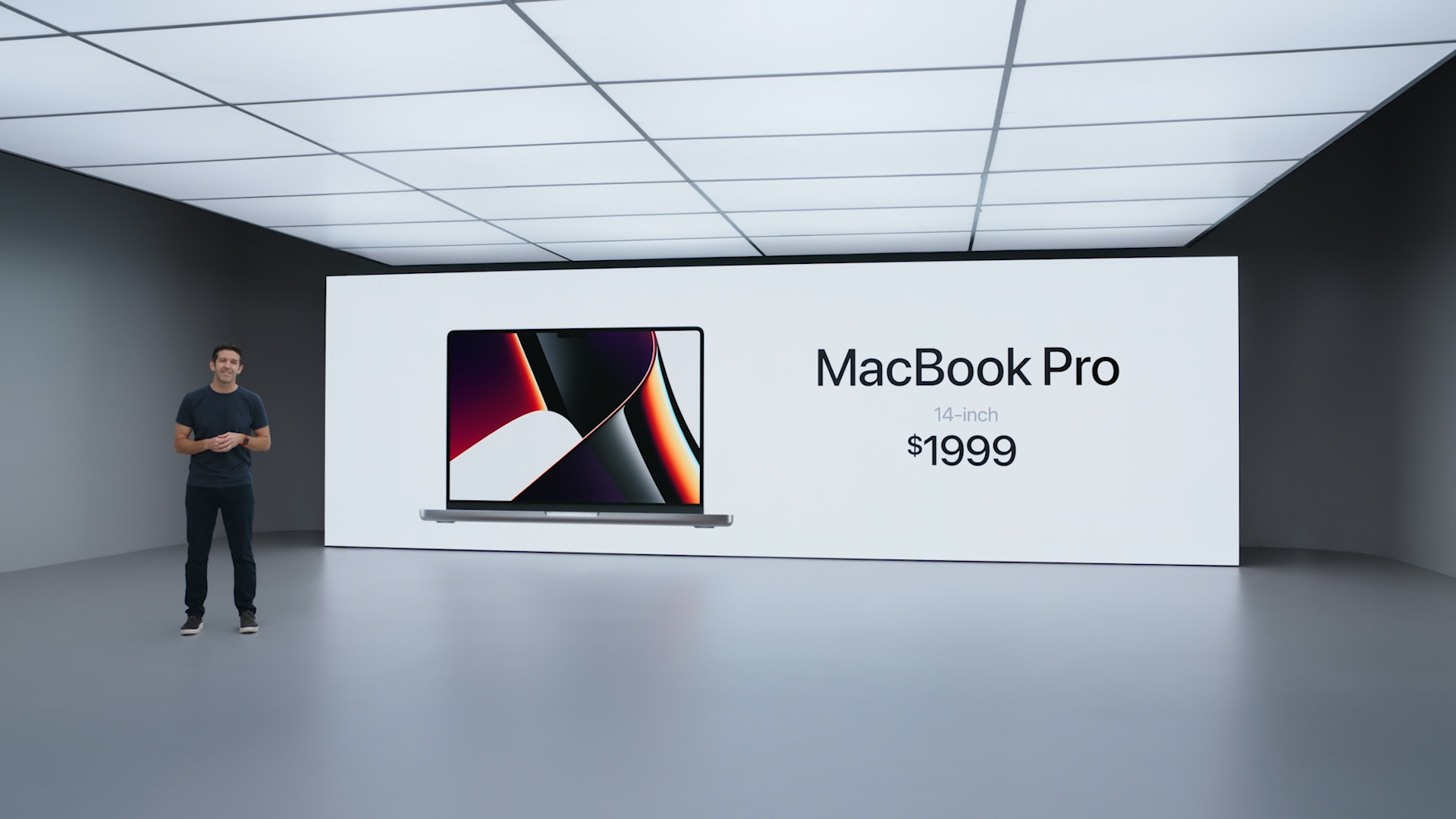

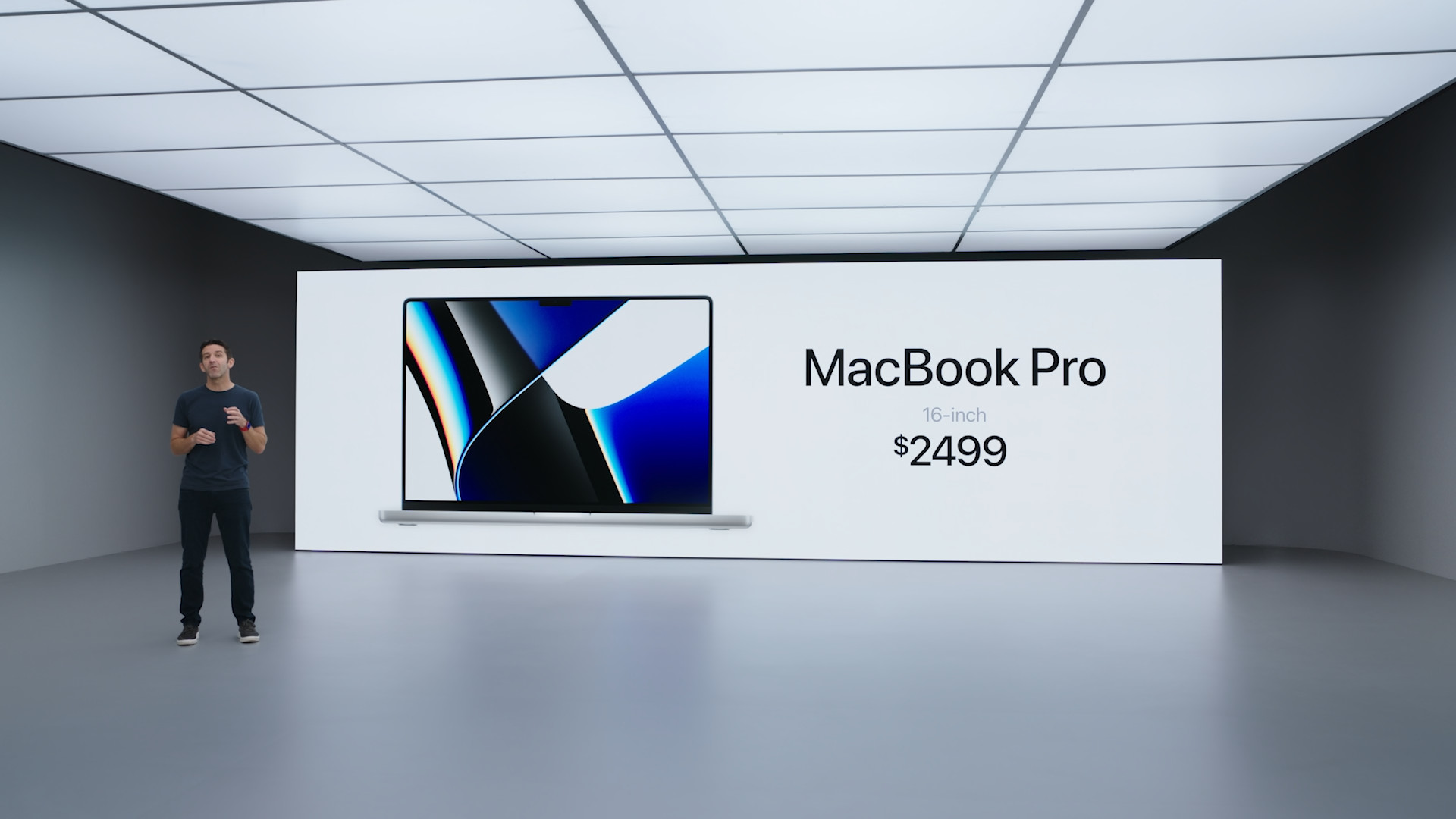

MacBook Pro (2021)

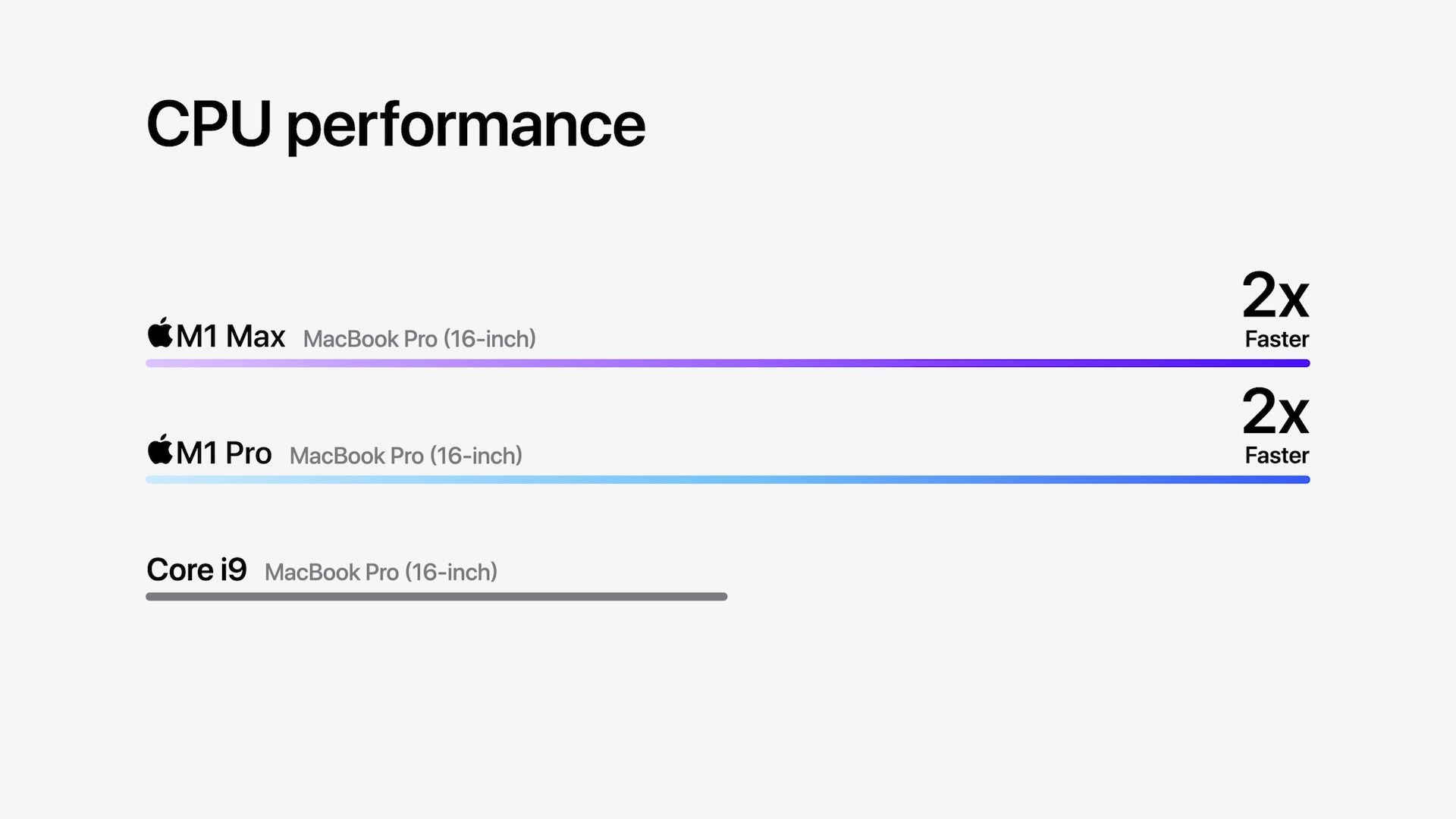

One of the keys to Apple's success is not working on hundreds of new products at once. Instead, resources are concentrated on a "handful" of projects that are expected to bear fruit, rather than being spread over many smaller projects. However, every single Apple product is reviewed at least once a fortnight by the executive team. Thanks to this, delays in decision-making are minimal. So, when you add up everything that has been said, you will realize that the product design itself at Apple really does not have to be an extremely long process.

It could be interest you

Production and revision

But if you already know what the product should look like, and when you equip it with the appropriate hardware, you also need to start manufacturing it. And since Apple is behind very limited in-house manufacturing, it has to outsource individual components to companies like Foxconn and others. In the final, however, it is an advantage for him. This will remove many worries for Apple and at the same time it will guarantee it to keep production costs to a minimum. After all, this approach has a significant market advantage that many other electronics manufacturers are now emulating.

However, the work of designers does not end with production. After obtaining the prototype, the result is subjected to revision, where they test and improve it. This alone takes up to 6 weeks. This is a relatively expensive approach, to have samples made in China, transport them to the company's headquarters, and then change some already prepared production. On the other hand, this is one of the reasons why Apple has such a reputation for the quality of its products.

Adam Kos

Adam Kos

I really wish they would make CAD software, but I know this will never happen, they will rather focus on photos, videos, presentations... sad, but it is an unplowed field